Mohawk Group is the world’s leading producer and distributor of quality commercial carpet and hard surface flooring with dedication to innovation, style, service, and sustainability. Influenced heavily by mother nature, Mohawk believes not only in their flooring solutions to connect its users with the environment but

also that it is their duty as a manufacturer to lead the way by example in net-positive, transparent products.

Using Health Product Declarations, Environmental Product Declarations, and Declare labels they lead the way in product transparency by offering over 500 products with Declare labels. They are redefining flooring with products that not only minimize climate impacts but also foster beauty and allow people to thrive.

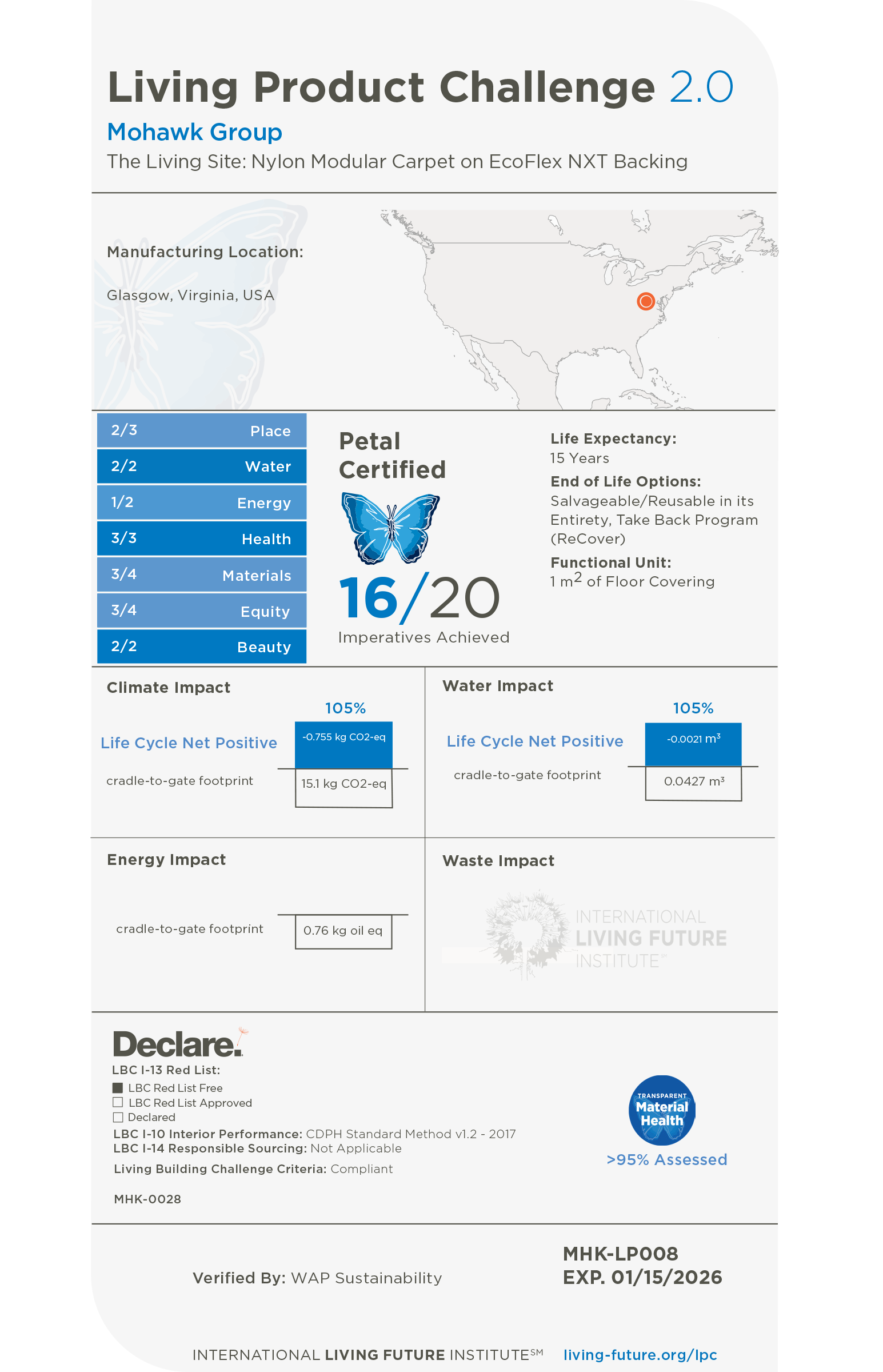

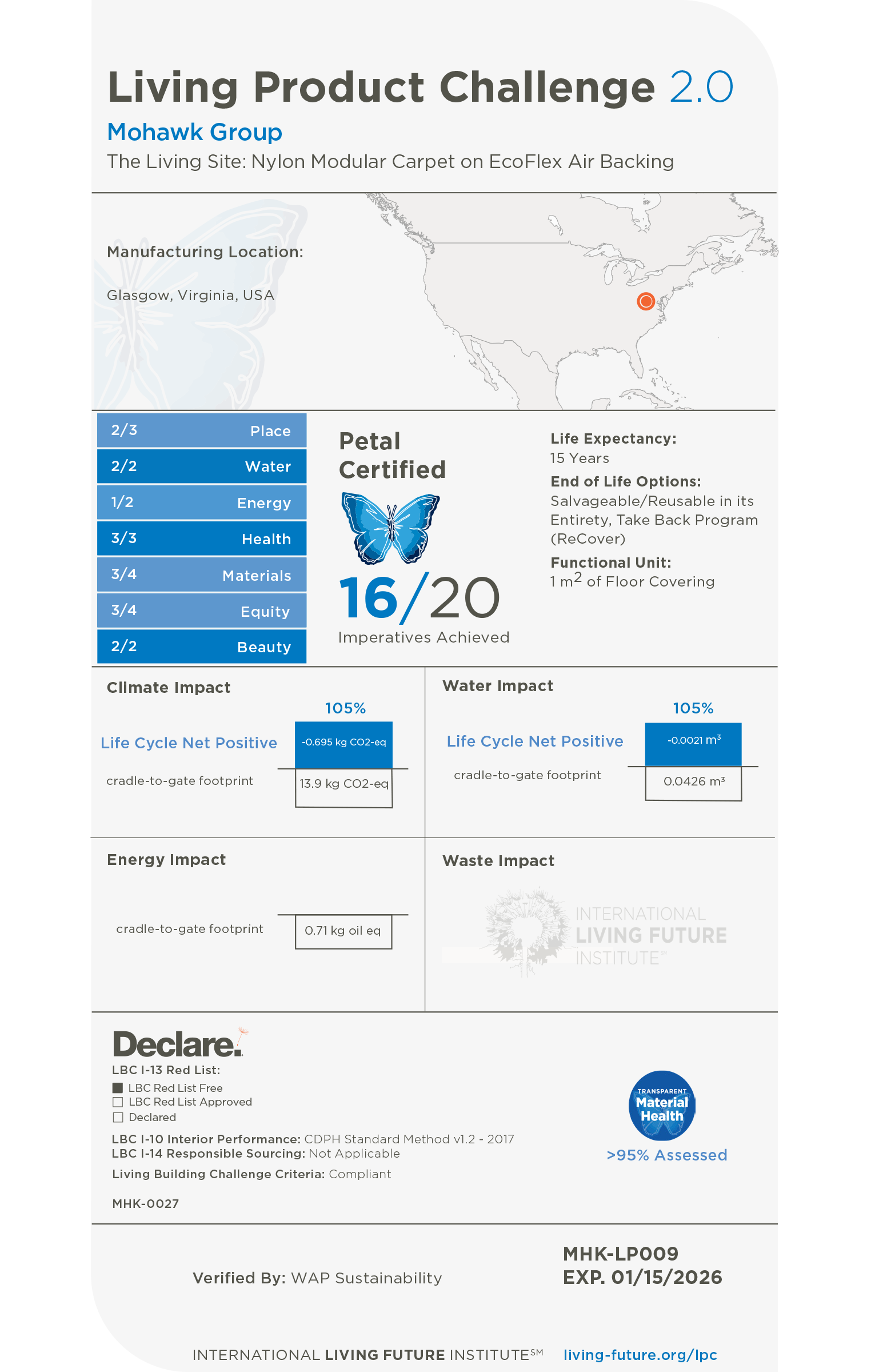

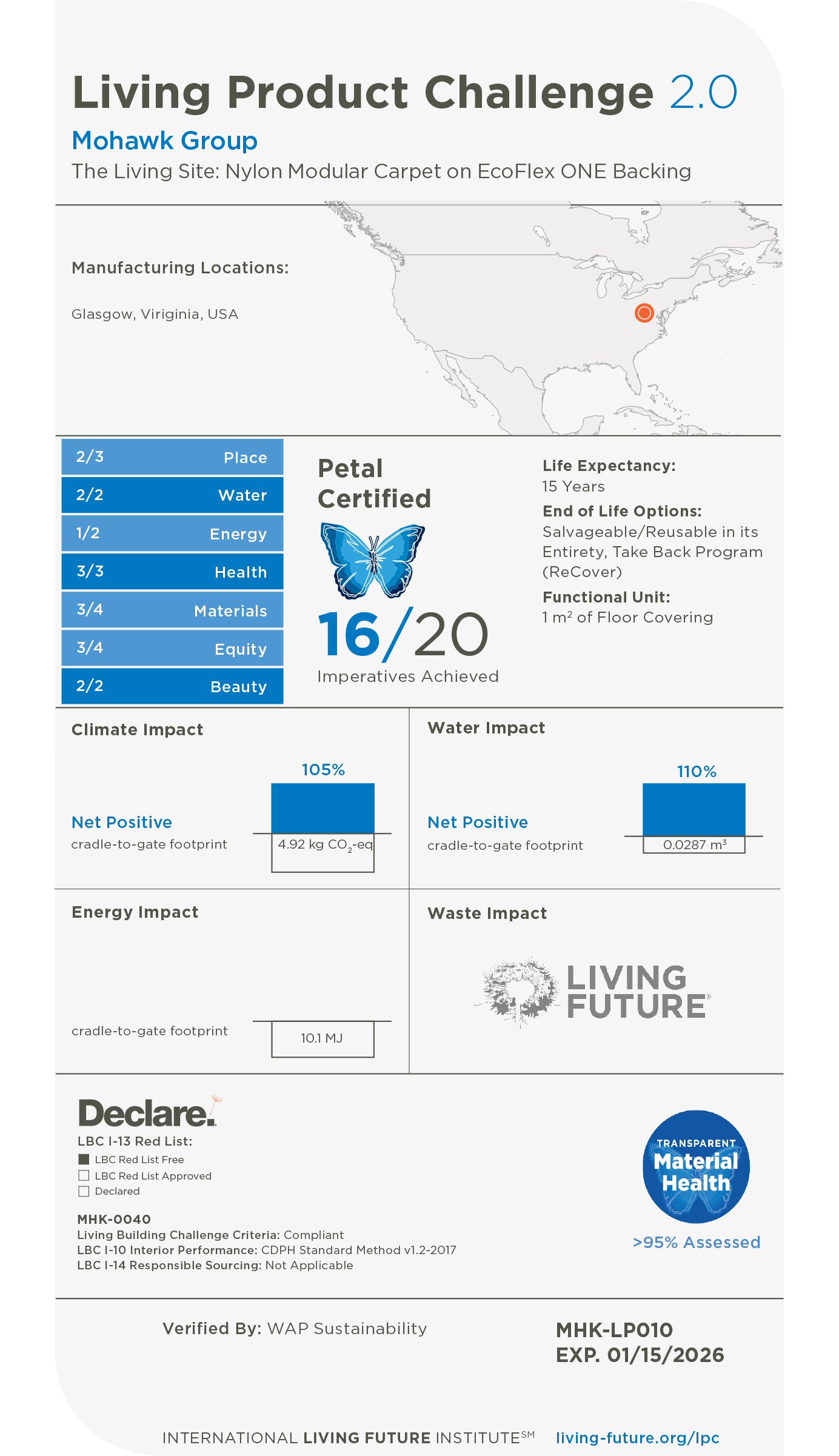

Mohawk’s Believe in Better commitment goes beyond product design and modification – it extends to employees, customers, and communities through various initiatives, collaborations, and platforms. The Living Product Challenge has inspired multiple commercial products from Mohawk Group and they have now accepted the challenge again by certifying their whole EcoFlex Production Line. By doing so, Believe in Better becomes more than a mantra—it becomes a way of working, a way of living. The certification of the EcoFlex Production Line means bringing the beauty, pride, and inspiration of having Living Product flooring to more buildings and people than before.

Top Hurdles to Certification

- Water Handprint

- Net Positive Carbon Imperative

- Obtaining FSC Certified Wood

Place Petal

01. Responsible Place Imperative

The manufacturer’s facility sits at the base of the Blue Ridge Mountains along the Maury River in Glasgow, Virginia. The Blue Ridge Forest ecoregion, where the town and facility reside, has one of the most diverse collections of plants and animals found in the world’s temperate deciduous forests. There are over 150 tree species, over 30 species of salamander, and over 200 terrestrial vertebrates that live in this region. Although this region has 3 species on the endangered lists, none of them are inhabitants of Glasgow Virginia. The town of Glasgow is surrounded by 3 national parks. The Mohawk facility, within Glasgow, sits on a 110-acre plot, whereas the building itself takes up 36 of those acres. Mohawk Group is committed to preserving the surrounding natural habitat. There are 2 National Wildlife Federation Certified Wildlife Habitats on facility grounds that provide shelter, food, and cover for local species of deer, rodent, birds, and insects. Mohawk’s facility grounds at Glasgow are also home to an 8-hive apiary, which assists with pollinating the local ecosystem, thereby further supporting local flora and fauna. Mohawk has a local employee who cares for the beehives and extracts the honey produced. Ecosystem support and beautification continue at the Glasgow facility as employees participate, and plan, to plant trees and wildflower gardens. By planting trees and wildflowers Mohawk employees support animal habitat and the success of local plants and agriculture.

03. Living Economy Sourcing Imperative

100% of the total budget inputs to the product are sourced within a 2000km radius of the Glasgow, VA site.

Water Petal

04. Water Footprint Imperative

The site of Mohawk’s Glasgow facility is in northwestern Virginia. It sits between a subtropical and intercontinental humid climate zones with an average temperature of 45 degrees Fahrenheit. Warmer months are characterized as having high humidity and moderate rainfall, while colder months experience less rainfall and lower humidity with decreased temperatures. On-site, the Maury River is located south of the facility within less than 1 mile.

Water is drawn from municipal owned wells. All wells are recharged by the James River. Two different wells are drawn from by the Glasgow facility; one well for process and another well for potable water. Potable water is used throughout the Glasgow facility for HVAC, restrooms, sinks, and water fountains. Water drawn for process use is primarily consumed by the Boiler Plant and Space Dye. The boilers are used for part of space dye, EcoFlex finishing, and building heat by steam. Space dye consumes water for yarn dyeing. Condensate from boiler steam is returned back into the boiler process and accounts for 50% of water supplied to it. In the dye process, water is used to saturate dye to yarn, then wash excess dye from the yarn, and finally clean up.

Water from one well and some from the town of Glasgow goes into HVAC, restrooms, and miscellaneous uses then towards an onsite treatment plant and back out to the Maury River. Another well is deemed only for process water; some goes towards miscellaneous uses but most goes into a water softener which strips out magnesium and calcium then into the space dye and boiler processes. That water then is also sent to Mohawk on-site Water Treatment Plant and finally out to the Maury River.

| Water consumption per unit of measure: | 0.0318-0.0427 m3 |

| On-site water annual use: | 110,443 m3 |

| LCA Unit of Measure: | kg oil-Eq |

| Life Cycle Analysis results for Energy: | m3 |

Water Hotspots

- NXT Steam Dryer

- Yarn Air Wash

- Tufting Air Wash

- Space Dye

- Latex Topical Mixing

Energy Petal

Energy use is allotted to the EcoFlex production lines based on the proportional amount of total production from the facility calculated in square yards of products. Since the location of Mohawk’s Glasgow facility has limitations for on-site renewable energy, due to the mountains, Mohawk has purchased renewable energy certificates, which will create positive social and environmental benefits.

06. Energy Footprint Imperative

Mohawk continues its sustainable solutions with their EcoFlex carpet tile products. Main uses for energy at Glasgow facility, the place of final assembly, include natural gas for heating and manufacturing processes, electricity for lighting, machinery, processing, air compressors, and air conditioning. Energy use is allotted to the EcoFlex production from the facility calculated in square yards of products. They use less energy and resources compared to other carpet tiles due to the dematerialization and use of recycled content. By using 55% recycled content, less raw materials are needed. EcoFlex NXT Air cushion product uses less energy in the manufacturing process because it is made from rPET fibers instead of traditional foam products and the cushion contains 90% or more post-consumer recycled content. Since the location of Mohawk’s Glasgow facility has limitations for on-site renewable energy, due to the mountains, Mohawk has purchased renewable energy certificates, which will create positive social and environmental benefits. Opportunities for further reduction of energy usage include continuing light saving opportunities with efficient new designed fixtures, improving insulation of steam, condensate, and chilled water lines with infrared identification to reduce energy and heat loss, utilizing best practices in electric motor efficiency due to losses and friction, and compressed air leak preventative maintenance through ultrasound leak identification.

Energy Hotspots

- Yarn

- Manufacturing Electricity

- Thermal Energy from Natural Gas

Health and Happiness Petal

Mohawk provides Glasgow employees with various mechanisms for them to live healthy and active lives. The Glasgow facility has one of Mohawk’s many Healthy Life Centers on site where employees can go to be seen for ailments, biometric screenings, and health coaching if necessary. A mobile dentist and mammogram center frequently stop on-site at the Glasgow facility where employees do not have to travel extra distances for subsidized, quality care. A health and wellness pilot program is underway at Glasgow facility – the program allows those who join to easily keep track of health-related metrics via online or through a free phone application. Employees can view upcoming fitness activities, read articles related to health and wellness, view healthy recipes, watch videos on supporting a healthy mind as well as diet, and log daily metrics.

Breaks throughout the day give Glasgow employees an opportunity to step outside and take in the nearby surroundings. Picnic tables have been placed right outside of the plant where breaks or lunches can be enjoyed while taking in the lush surroundings of the landscape which is situated in the foothills of the Appalachia Mountains. Earth Day activities give employees opportunities to beautify the area through flower and tree plantings, and an onsite honeybee apiary provides educational opportunities as well as assists in enhancing the regional ecosystem.

08. Red List Imperative

Mohawk Group eliminates Living Building Challenge Red List chemicals from its Nylon EcoFlex NXT and Nylon EcoFlex NXT Air manufacturing process and products. With the use of Declare labels, Mohawk discloses all ingredients used in a product to stakeholders and consumers to ensure it is free from causing negative health effects to consumers or the environment. Using ingredient disclosure labels like Declare allows people to make more informed decisions on materials they choose to put in their homes or workplaces, where most of the day is spent on average. Product packaging is also red-list free and does not threaten wildlife if disposed of appropriately.

DECLARE ID: MHK-0027, MHK-0028, MHK-0029

10. Human Thriving Imperative

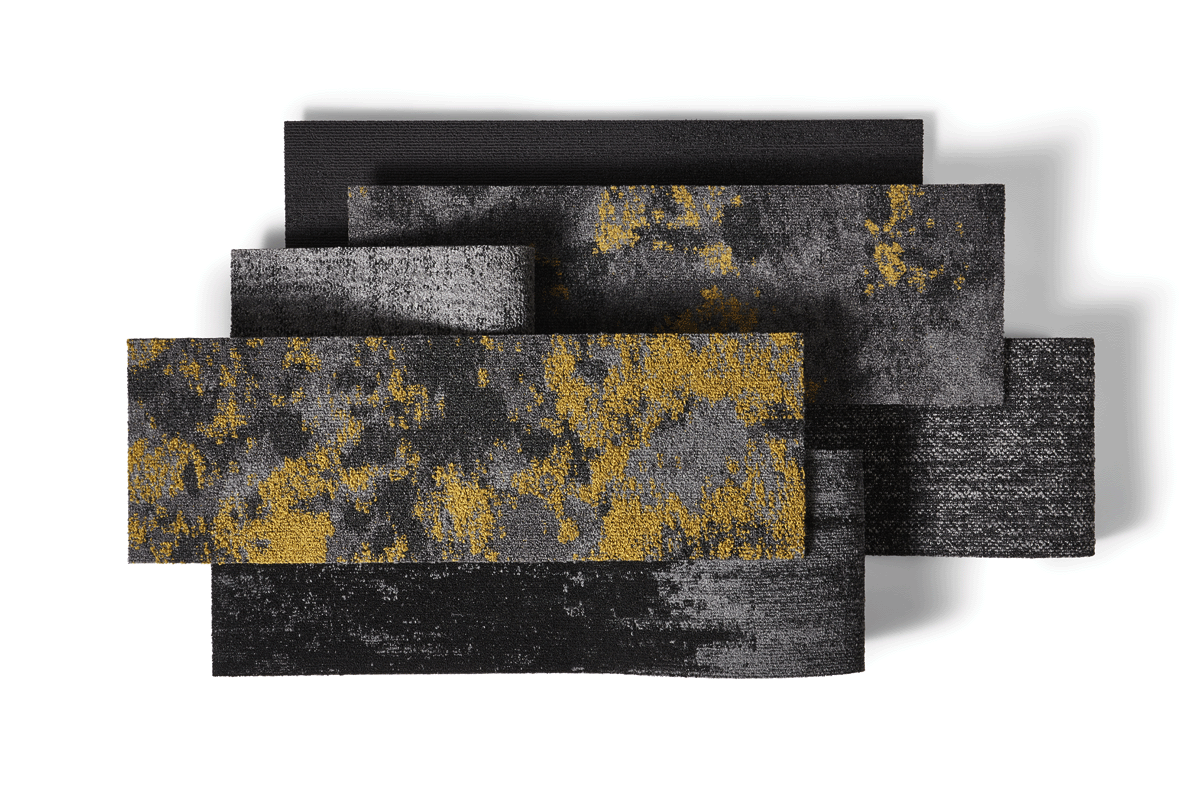

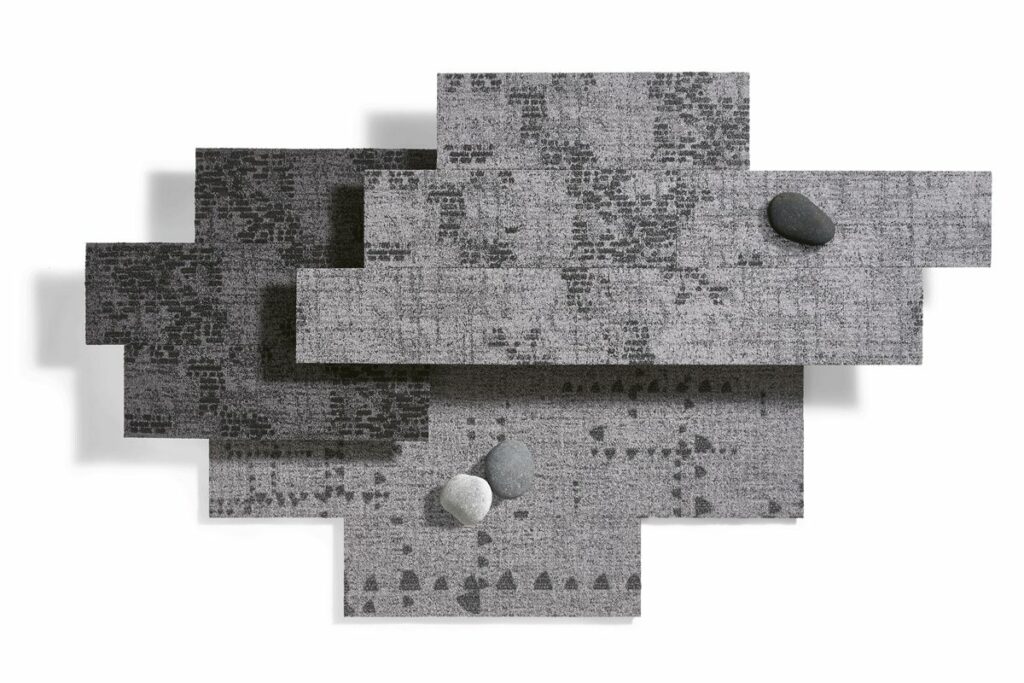

Mohawk is continuously inspired by the beauty of the natural world. Several collections that are made from the Glasgow facility in Virginia give an ode to the environment which sustains us through texture, pattern, and color. The goal of production of various collections is to enhance human connectivity to nature – both for employees and consumers. Mohawk Group designers are moved by biophilic design and create patterns that nurture people’s desires to be closer to nature. At the Glasgow facility, manufacturers produce the actual product and see every beautiful finished result that will be shipped out to consumers throughout the nation. The Glasgow facility sits in the Appalachian foothills by the Maury River and two wildlife habitats. Opportunities throughout each workday are available for employees to step outside the facility and enjoy the sounds, scenery, and wildlife of the onsite landscape. Events are held annually to get employees involved in the beautification of their workplace landscape; recent events include tree and wildflower plantings.

Materials Petal

11. Responsible Industry Imperative

Mohawk diligently communicates with suppliers on the use of sustainable materials. Currently, suppliers have Chain of Custody certification through the Sustainable Forestry Initiative (SFI). In 2019 Mohawk added a compensation category for recycled pallets to their driver program. There is a pallet pick-up pay that is used when drivers collect pallets and return them to Mohawk for reuse. From just one month, nearly 14,000 pallets had been recycled.

Sourcing FSC certified wood was not feasible at the time of certification due to the limitation of availability from suppliers. Mohawk has received an LPC Temporary Exception for suppliers having Chain of Custody certifications through SFI (Sustainable Forestry Initiative).

12. Regenerative Materials Imperative

Mohawk’s ReCover program provides customers the opportunity to divert old carpet in an environmentally friendly way with its US-based partner that will facilitate pre-approved international projects directly with customers and local diversion entities. Depending on the project location, customers have the opportunity to divert material locally regardless of manufacturer.

Beauty Petal

19. Inspiration and Education Imperative

LPC PAGE URL: https://www.mohawkgroup.com/sustainability/living-product-challenge

20. Beauty and Spirit Imperative

Design is always at the forefront of Mohawk’s product development. Understanding design’s ability to influence sustainable lifestyle and foster health and wellness is engrained from the beginning of the process. All the collections from the EcoFlex production line give an ode to biophilia and connect those who experience the product to place.