Teknoflor® Naturescapes HPD™ is the brand’s first organic sheet good made with ecuran, an organically-derived polyurethane composite material processed from plant-based oils such as castor oil and naturally occurring minerals such as chalk. This resilient sheet flooring product has all the advantages of sheet vinyl: durability, easy maintenance and versatility, but without the PVC. The product comes in twenty-four beautiful designs across three distinct styles that can be used independently or together.

Currently sold throughout the United States by Teknoflor and designed and sourced by Metroflor Corporation, Naturescapes HPD has an LBC Compliant Declare label (a nutrition label for building products). While both Teknoflor and Metroflor have a longstanding history of safe and sustainable practices, it is largely thanks to their work with organizations and collaborations like the International Living Future Institute (ILFI), the Health Product Declaration Collaborative (HPDC), and mindful MATERIALS that the environmental business focus at each company has expanded to include transparency, material health and social justice.

This has led the two companies to extensively examine their corporate culture and the products they bring to market, while also allowing them to set precedents in the resilient flooring industry – an industry they’ve both called home for decades. Teknoflor became the first company in the flooring industry to receive a JUST label, while Metroflor Corporation’s Aspecta division became the first to receive a JUST label for a factory based in China (and all of Asia, for that matter). Metroflor was the first company to have Declare labels issued in six languages for several of its Aspecta commercial flooring products, and was the first to have a Declare label issued for a multilayer modular flooring product.

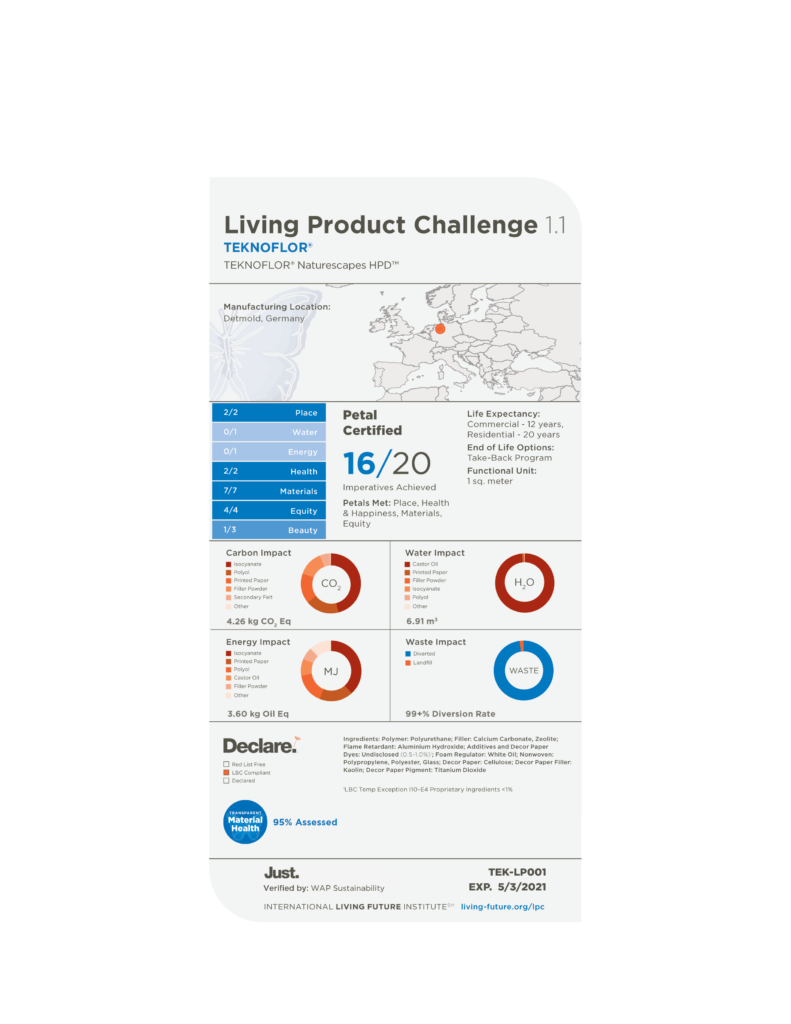

Despite such accomplishments, Teknoflor and Metroflor realized that the crown jewel of sustainability and transparency-based programs – the Living Product Challenge (LPC) – was one that they had not yet achieved. Tackling the LPC would first require an alternative to PVC-flooring. This made Teknoflor® Naturescapes HPD™, a polyurethane sheet flooring product that the two companies had been developing in conjunction with Windmöller GmbH, the natural choice for LPC certification. Shannon and Metroflor next secured the aid of WAP Sustainability Consulting, a firm whose employees had extensive experience as LPC assessors and consultants. Over the course of the next four months, the four companies poured extensive time and resources into the Living Product Challenge…with organization, open communication, and drive & determination allowing them to successfully reach their goal. Through their combined efforts, Teknoflor® Naturescapes HPD™ has become the first resilient flooring product to achieve Petal Certification under the Living Product Challenge.

TOP HURDLES TO CERTIFICATION

1) RED LIST FREE DECLARE LABEL

Products that are to receive a Red List Free Declare label are those for which the manufacturer has disclosed the chemical name, role/function, and, if applicable, CAS Registry Number of all ingredients at/above 100ppm in the product. The ingredients must also not appear on the International Living Future Institute’s Living Building Challenge Red List.

While Teknoflor® Naturescapes HPD™ met the second qualification for a Red List Free Declare label, it did not meet the first, as Windmöller GmbH (the product’s manufacturer) deemed that certain ingredients were proprietary in nature and could not be disclosed. Such ingredients, according to Windmöller, allowed them to offer a unique product that could serve as an alternative to traditional, PVC-based sheet flooring.

After discussions with Metroflor Corporation, WAP Sustainability Consulting, and the International Living Future Institute, Windmöller agreed to disclose 99% of the ingredients in Naturescapes HPD. This level of transparency, along with an absence of ingredients on ILFI’s Red List, allowed Naturescapes HPD to receive an LBC Compliant Declare label from ILFI – thus also satisfying certain requirements of Living Product Challenge certification. This also allowed Windmöller to keep private those ingredients that it deemed proprietary and were essential to ensuring its polyurethane-based products remained unique in the marketplace.

2) ENORMITY OF THE LIVING PRODUCT CHALLENGE

There are 20 Imperatives spread across 7 Petals as part of the Living Product Challenge (LPC), with each Imperative focusing on different aspects of a product, the company/ies that bring it to market, and the impacts that each has on our natural resources and on the global economy and global community to which we all belong. Delving further-in, a vast majority of the 20 Imperatives deal with multiple facets of a particular sphere of influence.

While this makes the Living Product Challenge one of the most (if not the most) comprehensive sustainability and transparency-based certifications available today, it also makes it one of the most challenging to achieve.

As such, it’s important that companies seeking to take part in the Living Product Challenge are aware of the following before they begin this journey:

- KNOWLEDGE – of what lies ahead. It’s important that you become intimately familiar with and understand the Living Product Challenge – its intent, the different levels of certification (Imperative, Petal, Full), the 7 Petals and 20 Imperatives it encompasses (the requirements of each Imperative and which Imperatives are “Core Imperatives”, i.e. required for any level of certification), the concepts of Footprints & Handprints, and the other ILFI programs that are incorporated into the Living Product Challenge (Declare, JUST). The best way to start is by pouring over the resources that have been made available at https://archive.living-future.org. In particular, download the Declare Manufacturer’s Guide, the JUST User Manual, and the Living Product Challenge Standard. When you’re done with those, contact ILFI to obtain a copy of the Living Product Challenge Documentation Requirements. A thorough familiarity of these documents will help prepare you for the journey ahead, though it will take time to obtain that level of familiarity. That leads us to the next point…

- TIME – make sure you allow yourselves plenty of it. The Living Product Challenge isn’t something that you accomplish in a day, a week, or a month. That being said, there’s also no established time-frame for the Living Product Challenge. The amount of time required will ultimately depend upon a multitude of factors, including (but not limited to): the complexity of the product and its supply chain, the number of companies involved in bringing it to market (i.e. whether or not the company seeking certification for the product is its manufacturer), the level of certification being sought, the number and degree of challenges you might need to overcome in order to fulfill certain requirements of the LPC, and the size, experience, and availability of the team you assemble to take-on LPC Certification. All of this ties into another important element…

- STRATEGY – it’s crucial to have one from the onset. Sound strategies for LPC certification should include the following elements / steps (not necessarily in order): determine the level of LPC certification you wish to attain (Imperative, Petal, or Full), list-out the Imperatives and Documentation Requirements that level of certification will require, identify any potential hurdles and preliminary ideas on how to overcome them, assemble and assign team members to each Imperative and/or set of Documentation Requirements (based on their availability and area of expertise), determine how frequently your team should meet to ensure you’re on-target for certification, and identify which of the Living Product Challenge assessors (i.e. firms) that have been pre-approved by ILFI will be involved in your certification. This brings us to the last point…

- EXPERIENCE – seek out those who have it. Some of the firms that serve as LPC assessors also offer their services as consultants. While their consulting services will come at a cost, it tends to be an investment well worth the return – as their experience can be extremely helpful in navigating the journey that is Living Product Challenge certification (especially if it’s your first time embarking upon such a journey). There are also other companies who have already been down a similar path and achieved LPC certification… or are currently attempting to do so… and would be willing to offer advice and insight to those who might need it. This is a journey you don’t need to go it alone, and truthfully shouldn’t – at least, if you want to get the most out of it.

3-YEAR PLAN

Shannon and Metroflor will identify and select an NGO with whom they will work to develop and distribute video content that encourages smallholder farmers in India to switch some of their existing crops to the castor oil-plant. Castor oil, one of the primary ingredients of the polyurethane in Teknoflor® Naturescapes HPD™, is a drought-resistant crop that can bring about economic benefits for farmers (can fetch revenue over 10 times its input cost within a span of four and a half months of its lifecycle) and can absorb 7 to 10 metric tons of CO2 per hectare.

3-YEAR PLAN IMPACT AREA: 6.06 kg CO2-eq per square meter of Teknoflor® Naturescapes HPD™

PLACE PETAL

01. RESPONSIBLE PLACE AND HABITATS IMPERATIVE

Manufactured in Detmold, Germany by Windmöller GmbH, Teknoflor® Naturescapes HPD™ is responsibly made. Opened in 2000, Windmöller’s Detmold manufacturing facility utilized predeveloped land and several of the existing buildings (hangars) that had previously been used by a former British Army helicopter unit (Rheinarmee), thus forgoing the need for more extensive site redevelopment and helping to reduce the facility’s impact on the biome in which it is located – a biome that over 350 different species call home (according to the World Wildlife Fund/WWF). Windmöller has since expanded its manufacturing facilities into several additional hangars that had previously been used by the same helicopter unit.

Measures have also been taken by authorities to protect the biodiversity that exists in and around Detmold. As a result, 3,181 (8.2%) areas in North Rhine Westphalia are officially categorized as “Nature Protection Areas”, especially those areas in which rare species have been found. Any activity (be it related to construction, industrial operations, or otherwise) that might have a negative impact on wildlife is forbidden in and around such areas. There are also regulations and procedures in place if-and-when an area that is already undergoing authorization or development for use as an industrial or commercial sector is declared as a “Nature Protection Area”. In such instances, the possible impacts that such developments might have on wildlife / nature is investigated and considered by planning and zoning officials.

02. HABITAT EXCHANGE IMPERATIVE

TEKNOFLOR AND METROFLOR CORPORATION SUPPORT THE WILDLIFE TRUST OF INDIA’S HUMAN-ELEPHANT CONFLICT MITIGATION PROJECT IN ASSAM, INDIA.

Teknoflor and Metroflor’s passion for this project is derived from both the project’s geographical relevancy to key elements in Teknoflor® Naturescapes HPD™ and from the companies’ belief in its core values. Naturescapes HPD utilizes castor seed oil in its organic polyurethane, which is a primary component of the product. This castor seed is often sourced from small farming villages and communities in India, which this program and its mission directly impacts. The Wildlife Trust of India strives to “conserve nature, especially endangered species and threatened habitats, in partnership with communities and governments,” which is a mission that resonates with our corporate stance on animal welfare.

The Human-Elephant Conflict Mitigation Project addresses an issue that begins with a fostering of animosity by farmers towards elephants that damage land as they migrate between habitats. This animosity can lead to the poaching of elephants in an attempt to protect crops, a primary source of livelihood. This project aims to equip members of such villages and communities with powerful search lights and blankets – tools they can use to divert elephants from nocturnal crop raiding in a humane and safe manner.

These efforts will also serve as a bridge between local community members and India’s Forest Service. Communities that would gravitate towards the poaching of elephants out of a need for their own self-sustainment will instead be actively involved in a project that seeks to protect elephants. Ultimately, such efforts will benefit both human and animal life by ensuring that one does not encroach upon the other – and establish a harmony between the two.

| Name of Habitat Exchange Project | Human-Elephant Conflict Mitigation Project (Assam, India) |

| Name of Participating Land Trust: | Wildlife Trust of India |

| Land Trust Website: | http://www.wti.org.in/ |

PLACE PETAL LESSONS LEARNED

Achieving the Place Petal involved a great deal of emotional appeal, broad product understanding, and teamwork. Through the development of Naturescapes HPD™ and the Living Product Challenge (LPC) certification process, the team was able to understand the true and vast impacts related to the manufacture of the product. In the flooring industry, it is somewhat common to focus solely on sales and rather rare for manufacturers and suppliers to develop an understanding of the amount of people, wildlife, and geography that are impacted or influenced by the products they bring to market. Our team was passionate about staying relevant and close to home through this process. For example, we chose the Wildlife Trust of India’s human elephant conflict mitigation project in Assam, India for its geographical relevance and also for the direct impact it can have on regional farmers, whom we will (also) educate about the benefits of castor seed farming. Our team has been overcome with intrigue and passion about the positive impacts its products make through every stage of production, starting with the very first castor seed. We will approach each and every new product with a different mindset as a result of our involvement with LPC certification.

HEALTH & HAPPINESS PETAL

Teknoflor® Naturescapes HPD™ is manufactured by Windmöller GmbH of Germany, and produced in its Detmold facility. Windmöller offers a wide variety of benefits and perks to its employees, including: a Corporate Health Management program, access to a network of fitness and wellness providers, sponsorship of outdoor running competitions, special workplace glasses, and a corporate doctor who provides routine monthly screenings.

Naturescapes HPD does not contain any chemicals that are classified as Carcinogens, Mutagens and Reprotoxics (CMRs) and does not introduce risk of exposure to those who are involved in the manufacture, use, and disposal of the product – making it safe for human health. The maintenance process requires no waxing or buffing, which aids in the decrease of airborne bacteria and chemical run-off that often results from standard waxing and buffing.

05. TRANSPARENT MATERIAL HEALTH IMPERATIVE

During the review period, all chemicals within Teknoflor® Naturescapes HPD™ were examined for potential material health impacts. Each chemical was assessed to provide analytical information about human & environmental health hazards across the value chain in order to determine how each chemical performs against multiple hazard endpoints, and to determine each chemical’s environmental toxicity and fate.

The authors of the material health assessment concluded that there are no chemicals in Naturescapes HPD that are seen as Carcinogens, Mutagens and Reprotoxics (CMRs) to those who might be involved in the manufacture, use, and disposal of the product. Thus, Naturescapes HPD complies with the requirements set forth by Imperative 05 – Transparent Material Health of the Living Product Challenge.

06. HUMAN THRIVING IMPERATIVE

Teknoflor® Naturescapes HPD™ is manufactured by Windmöller GmbH, a part of the Windmöller group with production sites in Augustdorf (headquarters), Detmold (facility at which Naturescapes HPD is produced), and Bad Oeynhausen. Windmöller GmbH greatly values social responsibility and is known as a family-owned enterprise with an open, team-oriented, informal working atmosphere.

Windmöller GmbH offers a wide variety of benefits and perks to its employees, some of which include:

- Corporate Health Management program, with such preventive offerings as: partially-paid 15 or 30-minute massages for back & muscle relaxation at the company’s location, free bottled drinking water, and a “fruit day” with free fruit in at least a two-week rhythm.

- Access to a network of sports, fitness, and wellness providers in the East-Westphalia region that includes fitness studios, swimming pools, physiotherapy practices, and a lot more. Windmöller pays over 50% of the monthly fee for every employee who enrolls.

- Company doctor who provides routine screenings on a monthly basis and is also available for other appointments or conversations.

- Free influenza inoculations.

- Special workplace glasses through the cooperation of a local optometrist.

Windmöller also encourages and fosters employee interaction with the natural world. For example, Windmöller will sponsor company running competitions in the region, with several of them taking the employees through forests or other natural environments. In addition, Windmöller has multiple outdoor seating areas that can be utilized by employees during their lunch breaks. Such seating areas give employees the chance to get outside and enjoy the beauty of nature.

HEALTH & HAPPINESS PETAL LESSONS LEARNED

Through fulfillment of the Health & Happiness Petal, our team developed a stronger value of the importance of corporate due diligence and understanding the values, operations and mission of our manufacturing partners. We are now also better educated on the value of quality materials and the effect they have during both the manufacturing process and use phase.

MATERIALS IMPERATIVE

Naturescapes HPD, currently available throughout the United States from Teknoflor, was developed in response to a need for alternatives to PVC-based flooring. While such a need has been driven by multiple industries, the largest has undoubtedly been healthcare – an industry whose members have often turned to Teknoflor due to the company’s focus on resilient sheet goods and its desire to add new-and-improved products to its ever-expanding portfolio.

Healthcare is one of the most intricate industries when it comes to flooring applications and the need for sustainable, healthy materials. The application requires not only consideration of the materials used, but also their exposure to light and heat and any odors they may emit.

Teknoflor’s product team has historically relied on the durability and flexibility of vinyl products and has built their brand on “high performance flooring” with pleasing and diverse visuals. Although they have focused on vinyl products in the past, they have recently seen a growing need for PVC-free products and product ingredient disclosures.

Knowing that their clients and sales representatives depend upon a high-performing set of flooring solutions, their team was challenged to find an alternative ingredient that would not harm the durability and resiliency of the product and would enable them to offer more than the standard chip design so often seen in PVC-free flooring products.

Polyurethane is a relatively new type of resilient flooring (compared to vinyl) and does not appear on ILFI’s Red List. This ingredient has enabled Teknoflor to provide its clients with a product that is both high-performing and visually appealing. Thus, it became the ideal material to serve as the basis of the first PVC-free collection under the Teknoflor brand.

07. RED LIST IMPERATIVE

The Third Party Verified LBC Compliant Declare label issued for Teknoflor® Naturescapes HPD™ means that while only 99% of the ingredients in the product have been disclosed to the public, 100% of the ingredients have been verified by an ILFI-approved assessor as being chemicals and/or substances that do not appear on the Living Building Challenge Red List. This has allowed the manufacturer of the product (Windmöller GmbH) to protect its proprietary information (i.e. certain ingredients), while also fulfilling the transparency and material health requirements of the Declare program.

Teknoflor® Naturescapes HPD™ is a sheet flooring product made primarily from unique polyurethane grades, with advanced sustainability achieved through the use of plant oil (i.e. castor seed oil) as a main polymer component. Some of the other major ingredients include chalk and fiber reinforcement layers of glass and polyester. Naturescapes HPD, currently available throughout the United States from Teknoflor, was developed in response to a need for alternatives to PVC-based flooring. While such a need has been driven by multiple industries, the largest has undoubtedly been healthcare – an industry whose members have often turned to Shannon Specialty Floors due to the company’s focus on resilient sheet goods and its desire to add new-and-improved products to its ever-expanding portfolio. Polyurethane is a relatively new type of resilient flooring (compared to vinyl) and does not appear on ILFI’s Red List. Thus, it became the ideal material to serve as the basis of the latest collection from Teknoflor.

08. LIVING ECONOMY SOURCING IMPERATIVE

PERCENT OF TOTAL BUDGET SOURCED FROM EACH DISTANCE ZONE

| Distance | Percentage of total budget |

|---|---|

| 1000 km | 100% |

09. RESPONSIBLE INDUSTRY IMPERATIVE

While the International Living Future Institute’s Declare program focuses on the ingredients of a product, the Living Product Challenge broadens the scope by asking manufacturers and suppliers to consider (amongst other things) materials that are involved in the different stages of the supply chain.

In the case of Teknoflor® Naturescapes HPD™, doing so made Teknoflor and Metroflor Corporation come to realize just how many wood-based products are required to manufacture, package, and ship the product. Although there aren’t many wood-based ingredients in Naturescapes HPD, there are seven different wood-based products used to package and ship it from the manufacturing facility in Germany to Teknoflor’s third-party warehouse in the United States: side protection, wrap paper, product labels, cardboard core, cardboard layer, roll-guards, and pallets.

Windmöller, the manufacturer of Naturescapes HPD, has committed to only using FSC-Certified wood in the manufacturing of the product, and only FSC-Certified wood and/or 100%-recycled wood for packaging and shipping (with the type of wood-source depending on the packaging or shipping component). Teknoflor has also committed to work with their third-party warehouse to ensure that any pallets used to ship-out the product to their US-based customers will be pallets that are made from salvaged and/or reclaimed wood. Together, these companies will firmly uphold the principles of responsible industry.

SOURCES FOR WOOD: Forest Stewardship Council (FSC) Certified wood, salvaged wood

DECLARE ID: SSF-0003

10. NET POSITIVE CLIMATE IMPERATIVE

India has come to hold a special place in the hearts of the employees of Teknoflor and Metroflor Corporation, thanks in large part to the Living Product Challenge (LPC). Both companies selected the Wildlife Trust of India and its Human-Elephant Conflict Mitigation Project in Assam to fulfill the requirements of Imperative 02 (Habitat Exchange), while Journeyman International received sponsorship for the design of two educational-based facilities in India – one in Andhra Pradesh and one near the Bay of Bengal – to fulfill the requirements of Imperative 16 (Equitable Investment).

It is once more to India and its inhabitants that Teknoflor and Metroflor have turned to satisfy the requirements of another imperative – Imperative 10 (Net Positive Climate). Under the requirements of this Imperative, Teknoflor and Metroflor must develop and, over the course of a three-year period, execute a plan by which the Carbon Handprint of Teknoflor® Naturescapes HPD™ eclipses that of the product’s (cradle-to-gate) Carbon Footprint. Such Handprints can be formed in one of three ways: engage with users to reduce carbon emissions through improved use of the product; take action outside of the product’s supply chain to reduce carbon emissions; purchase a carbon offset equivalent to the cradle-to-gate GHG footprint of the product.

The Carbon Handprint plan for Naturescapes HPD will see Teknoflor and Metroflor work closely with an NGO of choice to bring castor oil education and awareness (in the form of media content) to communities in suitable growing regions with a high number of smallholder farmers. Such farmers – defined as those marginal and sub-marginal farm households that own or/and cultivate less than 2.0 hectares of land – are a vital part of India’s agriculture and rural economy, constituting about 78% of the country’s farming economy. There are over 1 million smallholder farmers in India, 94% of whom are women.

Castor oil, one of the primary ingredients of the polyurethane in Naturescapes HPD, is derived from the castor oil plant (Ricinus communis) – a crop with significant economic and environmental benefits. The crop can fetch revenue up to more than 10 times its input cost within a span of four and a half months of its lifecycle, and is used as a component in over 3000 kinds of chemical products, in senior industrial lubricants, in dyes, in food additives, etc. The entire plant has economic value – from leaf and stem to the fruit. Furthermore, the castor oil plant is drought resistant – needing water once every 25 days. Also, castor can absorb 7 to 10 metric tons of CO2 per hectare and can thus help mitigate the effects of global warning. It is no wonder that castor is seen as a miracle crop.

LCA FUNCTIONAL UNIT: 1 square meter

LCA RESULTS PER FUNCTIONAL UNIT FOR CLIMATE: 6.06 kg CO2 eq

11. NET POSITIVE WASTE IMPERATIVE

The first step in any materials conservation management plan should be the creation of products that are non-hazardous from the start. That was the approach taken by Windmöller GmbH in the manufacturing of Teknoflor® Naturescapes HPD™. Once the product was known to not be hazardous to humans and the environment, its end-of-life became easier to manage.

Windmöller recycles every piece of waste that it can from its manufacturing process, including any paper products that are utilized. In cases where a material cannot be readily recycled, additional research projects are undertaken to determine viable recycling pathways. It is only after such research projects are conducted and any alternative solutions are exhausted that the manufacturer sends the materials to a waste-to-energy incineration plant, thus completely diverting manufacturing waste from landfills.

FINAL PERCENTAGES DIVERTED FROM LANDFILL:

Metals: N/A

Paper and Cardboard: 100%

Soil and Biomass: N/A

All others – combined weighted average: 99%

12. PRODUCT FIT TO USE IMPERATIVE

An organic sheet flooring product made with polyurethane derived from castor oil, Teknoflor® Naturescapes HPD™ is manufactured with a 2.5mm (0.098”) gauge and 0.25mm (10mil) polyurethane wear layer. Naturescapes HPD is warrantied to last for up to 12 years in commercial applications, including: healthcare, senior living, retail, corporate / office, academic, and hospitality environments. While high-grade sheet flooring products are traditionally specified for commercial applications, Naturescapes HPD is also warrantied to last for up to 20 years in residential applications.

Safety and performance should be equally important aspects of any product, and thus Naturescapes HPD has been tested according to the latest standards under each category. Naturescapes HPD achieved a Class I per the 2018 International Building Code (IBC) and NFPA 101 Life Safety Code when tested in accordance with ASTM E648, passed the requirements of REACH SVHC 174, ASTM F963 (Heavy Metals), and ASTM D7823 / CPSC-CH-C1001-09.3 (Phthalates), and achieved an Acceptable Slip Resistance Potential (SRP) when tested in accordance with ANSI/NFSI B101.3. Naturescapes HPD also performed well when tested per ISO 4918-Castor Chair (4.5-5.0 AATCC Rating after 25,000 cycles), ASTM F2753-Dynamic Rolling Load (Indentation: ≤0.004″), and ANSI / ESD STM97.2-Floor Materials & Footwear – Voltage Measurement (≤2.0kV).

While the ASTM specification standard for polyurethane sheet flooring products is currently in development by ASTM Committee F06, Naturescapes HPD has already been evaluated under many of the test method standards that will likely be part of the official specification standard. Such test method standards include: ASTM F1914 (Residual Indentation), ASTM F970 (Static Load), ASTM F137 (Flexibility), ASTM F925 (Chemical Resistance), ASTM F1514 (Resistance to Heat), and ASTM F1515 (Resistance to Light).

Teknoflor® Naturescapes HPD™ has been built and tested with both safety and performance in-mind, making it an ideal flooring choice for any commercial environment.

13. USEFUL LIFE DISPOSAL IMPERATIVE

Under the Teknoflor® Naturescapes HPD™ Reclamation Program, any Naturescapes HPD waste accumulated during the installation process can be returned to Teknoflor. This includes Naturescapes ‘scraps’ from newly-installed material, as well as Naturescapes material that is being removed from previous installations (i.e. at the end of its product-life).

Those interested in taking advantage of this program can initiate the reclamation process by calling Teknoflor at (800) 522-9166 or by emailing recycle@shannonspecialtyfloors.com. Teknoflor will send a short application form that is used to collect the data needed to arrange for pick-up of Naturescapes HPD material from the jobsite. Once Teknoflor has received and reviewed the completed application form, it will send nylon bulk-sacks to the jobsite for use in ‘bagging’ the material to be reclaimed. Each bulk-sack will hold roughly 1 ton (2,000 lbs.) of material. To arrange for pickup after the job is completed, simply contact Teknoflor at the same phone number or email address. Teknoflor will handle all logistics of the return, though the jobsite contractor may need to help the carrier pick-up the products to be reclaimed.

Reclamation should always make sound environmental sense and sound fiscal sense. Naturescapes HPD material reclaimed by Teknoflor will be shipped to a local facility, where it will be sorted and stored. Teknoflor will coordinate with its recycling partners to ensure proper end-of-life management. Teknoflor’s Reclamation Program is currently available in the continental United States, and is provided free of all charges with the purchase of Teknoflor Naturescapes HPD flooring.

MATERIALS PETAL LESSONS LEARNED

The truth is, it is very hard to operate outside of one’s comfort zone. Shannon Specialty Floors’ comfort material is vinyl and has been for decades. However, we acknowledge the need to expand beyond the historical scope of our materials. New materials mean different testing standards, composition, durability, and benefits from use.

Moving outside of our comfort zone required many different hands of experience, talent, and innovation, all of which inevitably led us to become masters of a new type of resilient sheet flooring, one that has the potential to revolutionize our industry. Through manufacturing partnerships, third party verifiers and a whole lot of teamwork, we were able to make a phenomenal product that will offer our clients transparency, sustainability, durability, and beauty.

EQUITY PETAL

14. EQUITABLE PRODUCT ACCESS IMPERATIVE

Teknoflor® products have traditionally been marketed and sold to the commercial sector, as most commercial projects require products that can meet the high-volume and/or harsh traffic conditions typically found in such applications. In addition, hospitals or other healthcare facilities have stringent infection-control requirements that call for (sheet) flooring to be installed with welded-seams.

As such, new construction and/or renovation projects in the residential market rarely-if-ever call for Teknoflor® products. However, Teknoflor would be pleased to provide Naturescapes HPD™ at a discounted price to affordable housing projects (at a price comparable to similar products).

15. RESPONSIBLE CO-PRODUCTS IMPERATIVE

Teknoflor, Metroflor Corporation, and Windmöller GmbH believe in responsible manufacturing of products for the building industry (i.e. the industry in which each company is solely and/or primarily invested). Each company affirms that it is not involved in the manufacture of weapons or armaments, tobacco products, violent video games, or illicit drugs. Furthermore, each company affirms that it is not involved in any industry that: engages in fossil fuel extraction, nuclear energy production or nuclear weapons manufacturing; facilitates payday lending, gambling, or the patenting of life; charges interest rates significantly in excess of market peers for comparable offerings.

16. EQUITABLE INVESTMENT IMPERATIVE

Journeyman International (JI) has been selected as the NPO that Teknoflor and Metroflor Corporation will sponsor under the requirements of Imperative 16 – Equitable Investment. This is due to the geographical relevancy of several of JI’s projects to a key element in Naturescapes HPD, and because JI’s humanitarian work deeply touched both companies. Teknoflor and Metroflor have come to sponsor two projects in India – a country from which castor seeds are sourced. Castor seeds are used to make castor oil, from which the polyurethane in Teknoflor® Naturescapes HPD™ is derived.

The first project is for the design of the Covenant International School and Community Hall, which will provide high-quality, no-cost or low-cost education for at least 300 poor, orphaned, and disabled children in Andhra Pradesh. Schooling in this region of India has become relatively expensive, thus making it difficult or even impossible for many children from poor and lower middle-class families to obtain a quality education. Lack of education often means that such children end up as laborers in the agricultural and construction industries. This project will include international school classrooms, a community hall for the village, and a home for approximately 160 physically challenged children.

The second project calls for the design of the Residential Primary School and Leadership Center, a 17,200 square-foot campus situated beside the Bay of Bengal that will enable 200 children to receive an education and will house students in 10 dormitories. The school will serve daily meals and will include a playground, residence for administrative staff, and a vegetable garden for on-site food production. This project will take into consideration both tropical climate and regional culture as it curates and expands upon local building practices, while also employing a design that will allow for natural daylight to be used during schooldays.

17. JUST ORGANIZATIONS IMPERATIVE

Teknoflor (formerly Shannon Specialty Floors, LLC) was proud to become the first company in the flooring industry to receive a JUST label. JUST is a program by which companies work with the International Living Future Institute to analyze and improve upon the corporate policies and metrics that gauge their level of social equity & equality. Each metric (or “indicator”) falls under one of six categories: diversity, equity, safety, worker benefit, local benefit, and stewardship.

Although Teknoflor had policies in place for most of the indicators under JUST, some of them were not formally published or were not available in a single location on the company’s intranet. Thus, some employees had a greater awareness or understanding of the company’s policies than others. Thanks to Teknoflor’s participation in JUST, all of its employees now have equal access to its policies.

While policies are a prerequisite for a JUST label, data is the means by which a company’s score under each indicator is determined by the Institute. Scores range from 0 to 3 stars, and can be based upon a single data point or multiple data points (varies with each indicator). Teknoflor scored 2 – 3 stars in 17 out of 22 indicators, with some 3-stars including: non-discrimination, gender diversity, ethnic diversity, pay-scale equity, positive products, charitable giving, and animal welfare.

Transparency is another crucial aspect of JUST. As such, copies of Teknoflor’s policies, along with its JUST label, can be found at justorganizations.com. This transparency has not only led to pride on the part of the employees of Teknoflor, given their company’s precedent and how relatively well it did under a large majority of metrics, but has also led to positive acclaim from existing and potential clients, alike.

EQUITY PETAL LESSONS LEARNED

Shannon Specialty Floors’ JUST label was achieved through a combination of teamwork, corporate analysis, and value positioning. Our team working together on the JUST label has been one of the highlights of our year to-date!

So often in an industry like ours, manufacturers and suppliers devote the majority of their time to external factors like sales, marketing, and client retention. However, the JUST label helped us look within our organization and corporate culture to focus on our values, mission, and employee happiness. It helped us look at our organization as a whole and align our priorities with our established values so that we may better serve our employees and our clients.

BEAUTY PETAL

20. INSPIRATION + EDUCATION IMPERATIVE

LPC PAGE URL: https://www.shannonspecialtyfloors.com/products-page/teknoflor-naturescapes/

SUMMARY OF PROCESS AND BENEFIT OF PURSUING LIVING PRODUCT CHALLENGE

Our pursuit of Living Product Challenge certification was difficult yet also enlightening and passion-inspiring. Each organization involved was required to participate and work together to achieve a common goal – a task that is truly constructive and illuminating.

Because of the Living Product Challenge, our organizations have all achieved elevated levels of ingenuity, camaraderie, and creativity. Through ingenuity, we found an alternative to traditional, PVC-based resilient flooring. Through camaraderie, we learned to work together and openly communicate in order to achieve goals and optimize timelines. Through creativity, we learned that Handprinting is truly an attainable concept and one that can be incorporated into everyday life.

The process taught us how to work together, ask the tough questions, and respectfully push the boundaries that exist within the resilient flooring industry. Together, we have brought a phenomenal, industry disrupting product to market and we could not have done it without everyone involved.