EVERETT, WASHINGTON

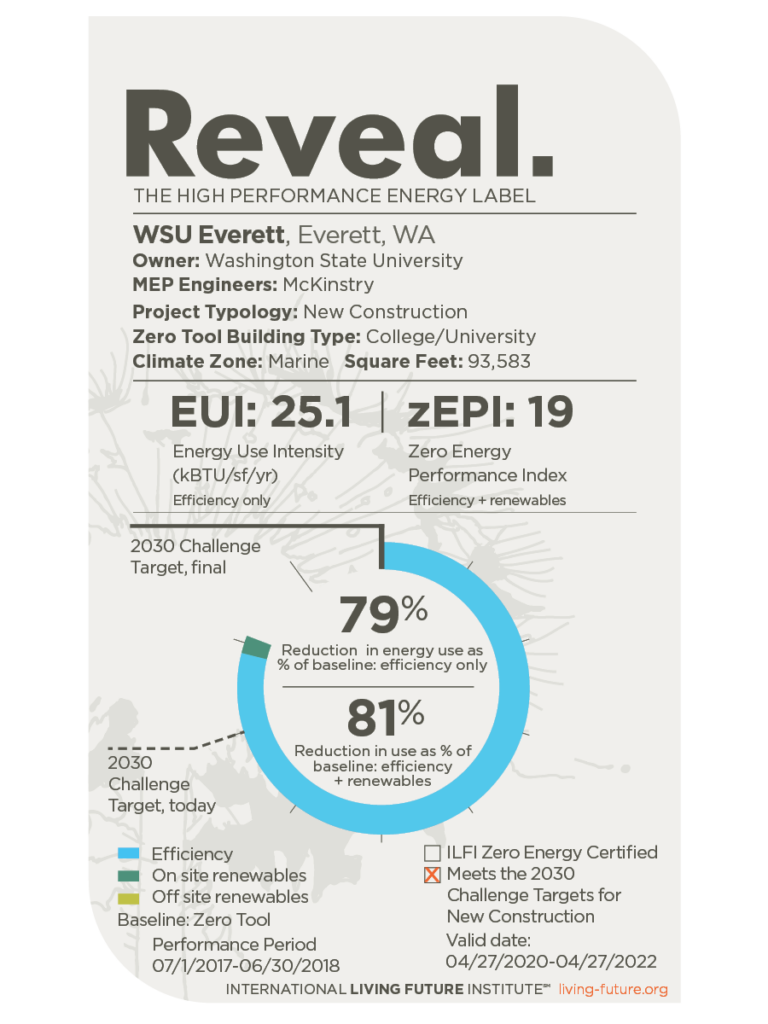

This building is the home of Washington State University –Everett, which includes Mechanical, Electrical, and Software Engineering, Data Analytics, Hospitality Business Management, and Integrated Strategic Communication Programs. The project was awarded as through a design competition and sought funding through a state grant which required that the design use 50% less energy compared to ASHRAE 90.1-2007, and achieve an operating EUI below 40.

The most economical system to meet the aggressive energy requirements and balance other project demands was determined to be a Variable Refrigerant Flow (VRF) with Dedicated Outside Air System (DOAS). This mechanical system was used throughout most of the building. The data center was designed with a hot-aisle containment strategy, and an air economizer system that allowed for increased supply air temperatures to the data center, and extended hours of “free cooling.” The VRF system was further integrated into the data center operation by providing VRF cooling units inside the hot-aisle of the data center. These units created an opportunity to recover heat from the data center equipment, use it to heat the Innovation Forum radiant slab, and provide cooling for the few hours of the year where outside air was too warm.An auditorium space on Level 1 was served by a dedicated displacement air system to conserve energy, and meet more aggressive acoustical requirements. In addition, reducing air leakage was identified as a core efficiency strategy, and was implemented through detailing and construction.A full-building air leak test showed a combined average of 0.217 cfm/ft²(45% better than WA State Energy Code).

The Innovation Forum is the heart of the building –a four-story atrium acting as agathering place for students, event venue, and link tomajor access points in the building. The use profile of the space, tall vertical profile, and access to perimeter façade at many orientations made for an ideal application for natural ventilation. McKinstry helped the architecture team locate and size operable windows, motorized dampers, and louvers to enable effective stack effect and cross-flow natural ventilation patterns. The team also settled on providing a radiant heated and cooled slab on Level 1 to reduce further concerns about being able to meet thermal comfort criteria. A full natural ventilation analysis was then used to refine the design and confirm that owner requirements for hours outside of typical design temperatures were met.

The project also includes a 78kW photovoltaic array and a 20,000-gallon cistern that captures rainwater and repurposes the water for 100% of the toilet and urinal flushing demand between September and June.