As the first tile manufacturer in Tennessee (est. 1986), Crossville is the leading American manufacturer of beautiful, sustainable solutions that advance the frontiers of tile design.

From introducing the nation’s first large-format porcelain tiles, to becoming the first and only net consumer of tile waste materials (meaning we recycle even more than we produce), to developing cutting-edge performance innovations that turn mere surfaces into “breathing” living environments—we are committed to pioneering products and practices that change the way the world views tile.

Crossville’s Retro Active 2.0 is a line before its time. When you look for tile that was designed to anticipate your needs, the diverse sizing of Retro Active 2.0 gives you options you’re sure to love. Design should reach in all directions to exceed expectations. We developed Retro Active 2.0 to include the best-selling colors and in demand sizes with a bold new finish option. 13 colors reflect a warm and cool neutral palette with exciting bright tones to enliven the mix, including super white and black. Design with 8 sizes in polished and unpolished finishes and our complementary linear texture pattern pieces while gaining the benefits of thru-body tile. Retro Active 2.0 pattern tiles, also in 13 colors, work in tandem or on their own to give dimension in a perfectly parallel presentation for a look of wainscoting, embellishment, or unique touch of texture. RetroActive 2.0—an evolution that is so remarkably versatile, fresh yet classic, you’ll wonder where this tile has been all your life. Ideal for any indoor application and exterior covered walls. See Crossville’s color coordinating patterns on the Retro Active Patterns page.

Crossville’s Retro Active 2.0 was designed by Michelle Lamb, co-founder and chairwoman of Minneapolis-based Marketing Directions, Inc. Established in 1987, Marketing Directions specializes in home furnishings color and trend forecasting, working extensively with clients to provide individual direction and color specification. A sampling of past and present clients includes Pier 1 Imports, ACCO, Hunter Douglas, Target Stores, Home Depot, Walmart, Gerber Baby Products, Tarkett, Hunter Fan, 3M, EK Success, Jo-Ann Stores and PetSmart. Ms. Lamb was also a founding member of the Sustainable Furniture Council, and she has served on the board of directors of WithIt and Color Marketing Group.

Michelle explains that the design of Retro Active 2.0 was intended to connect people to the colors of the world. From the warmth of Gulf waters and the chill of the Antarctic landmass to lush deciduous forests and raw minerals found in the earth, inspiration for Crossville’s newest Retro Active colors was drawn directly from nature. That is why these hues feel so comfortable and familiar. Bringing them into decorating palettes forges an instant connection with the natural world, and plays an important role in bringing the outdoors inside.

Shades 2.0 from Crossville derives its subtle beauty from nature’s elements. With the second iteration of this highly sought-after line, inspiration is taken from earth and water, resulting in the addition of Midnight – a deep dive into blue – and Russet -evoking rich, bountiful soil. These as well as Shades’ mineral rich warm and cool neutrals, are as foundational as earth itself. In Shades’ patterned tiles, a subtle pattern inspired by the veining system of a leaf reduced to bold and angular graphics, offer even greater creativity options for design.

Shades 2.0 is made in Crossville’s TN plant, known throughout the industry for its recycling of water and fired scrap, making Crossville’s tile manufacturing a highly sustainable process.

Color Blox 2.0 breathes new life into a longstanding line from America’s must sustainable tile manufacturer. The new colors added to the line are water and plant inspired and bring a sense of nature to interiors. Blue Suede Shoes, an original color, is now complemented with Little Boy Blue, a rich and royal hue. A new brighter green evoking the change of seasons – Spring Sage – refreshes the green offering. Bridging the gap between blue and green are Just Ducky and Celestial Horizon. The clean plaster-inspired graphic allows these natural hues to be the focus of a space.

Color Blox 2.0 is made in Crossville’s TN plant, known throughout the industry for its recycling of water and fired scrap, making Crossville’s tile manufacturing a highly sustainable process.

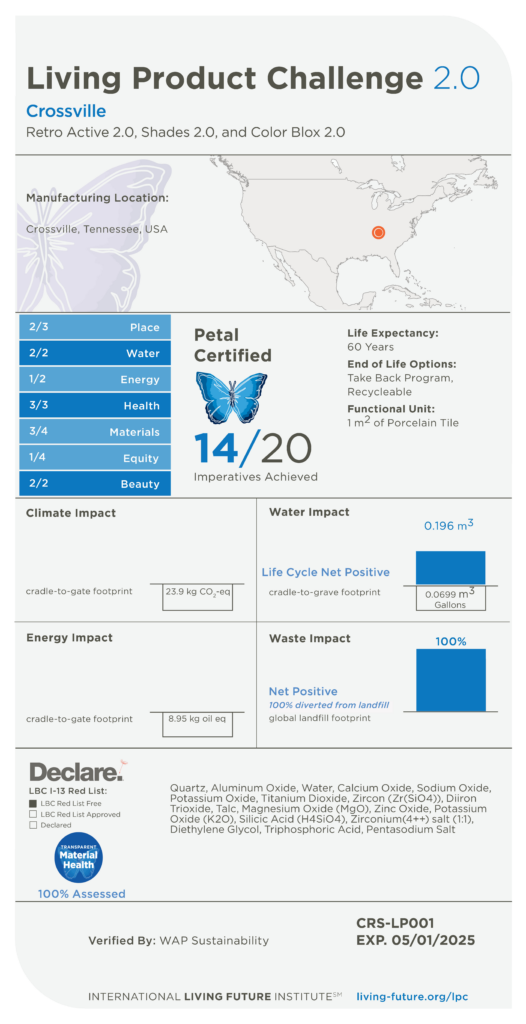

Place Petal

01. Responsible Place and Habitat Impacts

Crossville, Inc. manufacturers Retro Active 2.0, Shades 2.0 and Color Blox 2.0 in Crossville, Tennessee, located in Cumberland County, Tennessee. The ecoregion is described as Appalachian Mixed Mesophytic Forests and the biome as Temperate Broadleaf and Mixed Forests. The extraordinary forests of southeastern North America represent relicts of ancient mesic forests that once covered much of the temperate regions of the Northern Hemisphere. Today, examples of these forests can only be found in the southeast region of North America and in eastern and central China. The Appalachian Mixed Mesophytic Forests ecoregion encompasses the moist broadleaf forests that cover the plateaus and rolling hills west of the Appalachian Mountains. It extends southward into northwest Alabama and east central Tennessee. Moving north, the region includes eastern Kentucky, western North Carolina, most of West Virginia, southeastern Ohio and southwestern Pennsylvania. Mixed mesophytic forests acted as a mesic refuge during drier glacial epochs for a wide range of taxa. The long evolutionary history of the region and wide range of topographic and edaphic conditions have contributed to the development of the rich biota and abundance of endemic species, particularly in freshwater communities. Based on this description of the ecosystem, there is no perceived affect that our manufacturing operation has on this ecosystem.

Around Crossville’s facilities, current landscape activities involve hiring a crew of professional landscapers and mowers to maintain the existing grounds. Of the total amount of land owned by Crossville, a minimal amount is maintained next to the parking lots and entrances to allow for natural vegetation to grow.

Over the next 3 years, Crossville will identify ways to decrease the amount of maintained grounds and increase the natural vegetation growth on owned lands, including the use of native plants to allow for wildlife to thrive. Additionally, Crossville will work with the hired groundskeepers to operate without the use of petrochemical fertilizers or pesticides.

Water Petal

04. Water Footprint

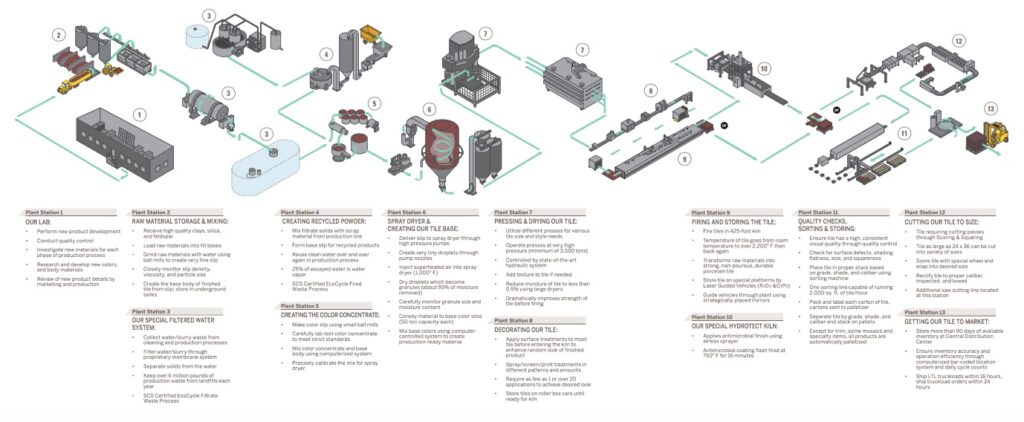

Crossville’s manufacturing processes are configured so that water is not used as a throughput; rather, it can be used, purified, and then used again cyclically—just as nature intended. 100% of Crossville’s manufacturing water needs are supplied by capturing manufacturing water in our closed loop water systems and by recycling industrial water.

Internally reclaimed materials, processed wastewater material, plus industrial scrap and unfired reject, are collected into a mixing tank. This aqueous stream is a combination of slurries and waters from the following processes:

- wash down of the spray dry units (which is the largest contributor to this stream)

- wash down of the spray drying area (this is from washing between batch operations to avoid color contamination between products)

- general spray-down and cleansing of the floors (including dry prep area, color room [relatively significant], and glazing area)

- water passed through scrubber units of the air pollution control emission stacks

- and regular washing as equipment maintenance.

This aqueous solution is diverted to the water treatment areas, passing through membrane filters where the material is separated from the water through a series of membranes specially designed for mechanical filtration (as opposed to requiring chemicals) that are regularly cleaned for reuse until they need to be replaced. This membrane filtration system works like a coffee filter – material builds up over time slowing down the flow. The solid material is then collected and used as recycled materials in the product while the cleaned water is recirculated back into the production process to be mixed into the porcelain production slurry.

During the production of the certified products, water (30% of slurry) is added to dry ingredients (70% of slurry) to produce a slurry which is then formed and dried to produce the porcelain tiles. Calculating the water requirement for the products under certification results in 283,777 gallons required for certification year 2020.

| Water consumption per unit of measure: | 0.0699 |

| On-site water annual use: | 283,777 gallons (product share total) |

| LCA Unit of Measure: | square meter |

Water Hotspots:

- Manufacturing – Electricity

- Material – Water

- Packaging – Cardboard

- Manufacturing – Natural Gas

- Material – Feldspar

05. Net Positive Water Imperative

To ensure Crossville’s Living Product Challenge certified products remain net positive with the on-site water requirement, Crossville utilizes a closed loop recycling system to collect materials and water from various manufacturing processes, including:

- Wash down of the spray dry units (largest contributor)

- Wash down of the spray drying area (washing between batch operations to avoid color contamination between products)

- General spray-down and cleaning of the floors

- Water passed through scrubber units of the air pollution control emission stacks

- Regular washing as equipment maintenance

The start of the Crossville manufacturing process begins with a blending of solids and water. Throughout each stage of the manufacturing process, there is expelled waste and water than can be captured, separated, and reused. Crossville defines this process as its EcoCycle Waste Process.

During the production of the certified products, water (30% of slurry) is added to dry ingredients (70% of slurry) to produce a slurry which is then formed and dried to produce the porcelain tiles. Calculating this requirement for the products under certification, we get a requirement of 283,777 gallons for 2020.

Given the production of 5,884,384 gallons of recovered water and the required 283,777 gallons of water for the production of the certified products, they are considered net positive. Furthermore, the recovered water is over 20 times the amount of water required for the 2020 certified products so there is room for growth within the certified products while maintaining the net positive water status.

Energy Petal

06. Energy Footprint

Crossville utilizes both natural gas and electricity for its production processes. Electricity is purchased from the utility provider and it used for multiple manufacturing processes, including, but not limited to: mixing, material conveyance, color application, water filtration systems, various other machinery and computers. Natural gas is purchased from the utility provider and is used primarily to heat up and dry the tile slurry to create the final porcelain product, similar to a kiln process.

Due to the significant demand in energy use in the drying process, this is where the biggest reduction projects can occur. Crossville’s energy team is consistently looking at ways to use alternative forms of energy other than natural gas and has been testing ways to better capture and recirculate heat from this process.

| Energy consumption per unit of measure: | 8.95 |

| On-site energy annual use: | 22,402.72 therms / 1,319,384.58 kWh (product share total) |

| LCA Unit of Measure: | kg oil eq |

Energy Hotspots:

- Manufacturing – Natural Gas

- Manufacturing – Electricity

- Materials – Feldspar

- Packaging – Cardboard

- Materials – Ball Clay

Health & Happiness Petal

At Crossville, our culture is and has always been based on one simple business ethic; “do the right thing”. We can think of no better way to do the right thing than to take proven environmental principals and unite them with Crossville’s manufacturing processes, to create truly sustainable products that are both economically practical and environmentally favorable. Crossville, Inc., is one of the largest employers in Cumberland County, Tennessee. As such, we take pride in being able to provide a workplace that puts people first. Our employees are our most important asset, and many of our employees have been with us for all 30 years of operations. We are proud to provide jobs full of opportunities, corporate and community responsibility, and provide employees an engaging place of employment for all of our employees.

Crossville’s Health Product Declaration (HPD) and Red List Free Declare label provide standardized formats for reporting product ingredients and associated health information. The Declare label and HPD objectively provide the critical information needed to support accurate supply chain disclosure and informed decisions by building designers, specifiers, owners, and users.

At the core of our products disclosures are eight key suppliers that share our passion for the environment, good design, and minimal impacts. Representing the states of Tennessee, Georgia, and North Carolina, these suppliers, which are located within 200 miles of Crossville, represent 85% to 95% of all raw materials depending on US manufactured product style.

08. Red List Imperative

Crossville’s Health Product Declaration (HPD) and Red List Free Declare label provide standardized formats for reporting product ingredients and associated health information. The Declare label and HPD objectively provide the critical information needed to support accurate supply chain disclosure and informed decisions by building designers, specifiers, owners, and users.

At the core of our products disclosures are eight key suppliers that share our passion for the environment, good design, and minimal impacts. Representing the states of Tennessee, Georgia, and North Carolina, these suppliers, which are located within 200 miles of Crossville, represent 85% to 95% of all raw materials depending on US manufactured product style.

| Declare ID: | CSV-0001 |

09. Transparent Material Health Imperative

Crossville, Inc. commissioned a Material Health Assessment as part of its pursuit of the Living Product study. This Material Health Assessments was conducted in accordance with the Living Product Challenge Standard Version 2.0 and the Living Product Challenge 2.0 Transparent Material Health Guide. Primary data were provided by Crossville, Inc. and its suppliers.

WAP Sustainability Consulting was contracted to conduct the Material Health Assessment and complete this Material Health Assessment report. Primary data was collected, and quality assured through efforts of both WAP Sustainability and Crossville, Inc.

10. Human Thriving Imperative

From its beginnings 30 years ago, Crossville, Inc., a United States owned and operated tile manufacturer, has maintained a sustainable mindset as a socially conscious method of doing business. Crossville has always considered the diligent pursuit of stringent environmental goals for internal air quality, outside air emissions, and wastewater discharge as basic and fundamental. Environmental stewardship extends throughout the company, our employees, their working environment, our community, and the innovative porcelain tile products that continue to make it all possible.

At Crossville, our culture is and has always been based on one simple business ethic; “do the right thing”. We can think of no better way to do the right thing than to take proven environmental and socially responsible principals and unite them with Crossville’s manufacturing processes, to create truly sustainable products that are both economically practical, socially inviting and environmentally favorable.

As a Curran Group Company, Crossville and Curran Group share the same Family Values.

- Family, owned and operated, focused on our family of employees. This “people first” approach has always led to our success.

- Respect, always mindful that “people first” works from the inside out. We infuse fairness and professionalism into all that we do. “Doing the right thing”, in business begins with respecting the value of your employees who pass it on to our customers, community associates, and vendors.

- Partnership, we align with people who share our core values and exceed our expectations. Working together we all succeed.

- Integrity, we have built a company and working culture steeped in character and community, it holds up through good times and hard times! We abide by unwavering standards of ethics and walk-the-talk principles.

- Improvement, today’s innovation, tomorrow’s success. We are constantly planning, innovating, improving, and giving back. As we reach for a successful business future, we do so confident in the foundation of our values, employees, and community.

Our family values in practice mean that we are committed to providing manufacturing facilities that provide excellent working conditions that promote positive health and productivity of our workers and the greater Crossville community.

And we take our role in the Crossville community to heart. Crossville, Inc., is one of the largest employers in Cumberland County, Tennessee. As such, we take pride in being able to provide a workplace that puts people first. Our employees are our most important asset, and many of our employees have been with us for all 30 years of operations. We are proud to provide jobs full of opportunities, corporate and community responsibility, and provide employees an engaging place of employment for all our employees.

One way we create a great workplace is with the design of the interiors of our facilities. When you arrive at a Crossville facility you will notice our focus on interior aesthetics. We want our facilities to be bright facility, clean, and fresh. We take great pride in the look of our facility as a warm and inviting place for our employees. We provide access to daylight, doors that open to outside with outdoor seating and break facilities and ergonomically designed work stations. Our facilities also take into consideration indoor air quality, having air exchange systems that flush the air inside our facilities on a regular frequency (depending on temperatures and humidity).

External to the facilities, you will see natural landscapes and spaces for employees to interact outdoors. We have picnic tables, and seating areas, walking paths and lush landscaping.

While we think we provide a great work environment for our employees, we also track our employees’ perceptions of our company via a Survey of our employees to collect feedback on our overall environmental, social and governance performance. This feedback is collected via an annual process, but we also track other employment feedback via reviews, exit interviews, and other employment-based sustainability performance indicators.

Materials Petal

The production of tile can be traced back to 24,000 B.C. and is recognized as one of the most ancient industries on the planet. The combination of naturally occurring materials like clay, feldspar, and silica combined with heat has proven to be a useful product that has withstood the test of time. While our technologies, techniques, and designs have improved through time, the concept of making tile is the same. We design tiles made of naturally occurring earth materials, fused together with heat. When the tiles have reached the end of their useful life, their design allows the materials to be reused through a basic grinding and recovery process. The result is a product with an infinitely circular lifecycle.

11. Responsible Industry Imperative

All packaging for Retro Active 2.0, Shades 2.0 and Color Blox 2.0 is SFI Certified through Georgia Pacific. FSC packaging was not available from any of our packaging suppliers.

Exception used: MT-009 Alternative Forestry Certifications for Product Packaging

12. Regenerative Materials Imperative

Crossville’s products are created with many different ingredients, most of which are mined materials. The top five most impactful materials are all mined materials, including feldspar, clays, sand, and quartz. When choosing materials, a requirement for durability after firing is of primary concern. Within this constraint, materials are chosen that are readily found in nature, with preference going towards locally produced materials. Additionally, recycled materials from post-industrial toilet scrap and captured Crossville scrap are used at the highest rate possible. Carbon-sequestering and bio-based alternatives are not available at this time. It is because of this that the current material selection is deemed the lowest impact possible. That being said, Crossville’s engineers are continuously looking into various additives and other alternatives to decrease the quantity of material needed to further lower the products’ impacts.

In addition, Crossville, Inc.’s revolutionary Tile Take-Back™ Program has helped collect and recycle millions of pounds of fired, post-consumer porcelain tile in the United States, enabling us to maintain net waste consumption at our plants since 2012. It’s a program we’re proud to have pioneered, and one that we welcome you to join.

13. Net Positive Waste Imperative

Crossville’s original mission was to reuse every pound of ceramic raw material into fired tile that was sold. This included solids from wastewater, unfired powder and scrap, and fired scrap. While this is an ambitious goal, our progress to date signifies that we have become a net consumer of waste, meaning we recycle more waste into new product than is sent to the landfill.

In 2011, Crossville became the first manufacturer to achieve certification of its tile waste recycling programs through Scientific Certification Systems (SCS), an independent, third-party leader in verifying sustainability claims. Crossville has developed two primary means of recycling tile manufacturing waste that would otherwise be sent to local landfills: its EcoCycle Fired Waste Process™ and its EcoCycle Filtrate Waste Process™.

The collection of fired tile scrap and filtrate waste from our own production process, specifically for crushing, grinding, and reuse, was established in 2002 and expanded in 2005. Before this time, waste material was being sent to the landfill. Material sent to the landfill is expensive because it costs money to send to the landfill, results in wasted raw materials, and does not contribute to sales.

The entire process starts with the collection of unusable fired tiles at Plants 1, 2, and 4, which are discarded and placed in surge bins in the areas where they are collected. This “hard scrap” is collected from three areas of the operations: broken and chipped edge tile (a large portion of the fired scrap), large tiles broken during scoring into smaller tiles (a small portion of the fired scrap), and those damaged in the packaging department during preparation for shipping. Filtrate solids are collected from water discharge, dried, and reintroduced as reclaimed raw materials.

As a net-consumer of waste, Crossville procures additional waste materials three different ways.

TOTO USA PARTNERSHIP

We partner with TOTO® USA sanitary wares to recycle pre-consumer fired porcelain that would normally be discarded, into raw material for new tile. Just a few years into the program, Crossville has become the first net consumer of tile waste (meaning we recycle more waste than we produce), diverting millions of pounds of raw material waste from landfills. Crossville partnered with TOTO, the world’s largest plumbing products manufacturer, to recycle pre-consumer waste, converting TOTO’s sanitary toilet ware waste into powder form, used in their toilet manufacturing process. TOTO’s unique fired porcelain, when crushed into very small pieces, becomes the raw material from which Crossville begins producing porcelain tile. By “upcycling” TOTO’s waste product, we created a high-quality raw material.

- 2020 Recovered TOTO Amount – 779,880 pounds

ECOCYCLE WASTE PROCESS®

We have developed two primary means of recycling manufacturing tile waste that would otherwise be sent to local landfills: EcoCycle Fired Waste Process™ and EcoCycle Filtrate Waste Process™. Both proprietary processes have been verified by Scientific Certification Systems (SCS) as enabling Crossville to successfully recycle nearly 12 million pounds of previously discarded filtrate and fired waste every year.

- 2020 Fired White Scrap Amount – 375,229 pounds

- 2020 Fired Dark Scrap Amount – 2,522,478 pounds

- 2020 Unfired (green) Scrap Amount – 4,356,681 lbs

- 2020 Recovered Filtrate – 2,421,873 lbs

TILE TAKE-BACK PROGRAM®

While many tile manufacturers, including Crossville itself, had been successfully reusing powders and unfired tile, both pre- and post-consumer fired porcelain tile (tile in its finished state) was considered non-recyclable. Every year, manufacturers dumped hundreds of millions of pounds of damaged, scrap or otherwise unsellable fired tile into landfills. Additionally, there was no known environmentally friendly way in which to dispose of previously installed, post-consumer tile. All that changed in 2009, when we introduced the Tile Take-Back Program.

- 2020 Data included in values above.

By converting scrap into a reusable material and reducing the amount of scrap with more efficient processes, Crossville has come closer to a close-loop process, diverting waste from landfills, and reducing the amount of raw material extracted from the Earth for production of our tile products.

Excess material from the press, as well as dust and other “dry” material (considered greenware) do not go through the wastewater treatment process, as they are separated as green waste and managed as solids. The dust collection system, along with other factors, assists in bringing the concentration of wastewater material up to allow spray drying. Since this material does not go through the elaborate treatment and reprocessing that the wastewater slurry does, it is classified the same as the unfired, unused greenware. Dust collection material is from the baghouse; other dry material is swept up, vacuumed, and collected in large bags under the press, as well as shoveled from other areas. Together this material makes up the greenware—and this is added to the recovered filtrate (the recycled material). The Roo is then spray dried, molded, pressed, and fired into the specific products to be certified.

Based on wastewater treatment methods, site observations, and flow diagrams, it is clear that the material of concern is a byproduct of primary production, and until recovered (using non-conventional methods) is considered a waste. Without considerable effort and expense, it is not possible to incorporate the material back into any tile making process, including the one that generated it, as in its effluent form is primarily water. Conventional tile manufacturing does not attempt to recapture this material because of cost, and of the requirements of work and additional system complexity.

All production waste is reused within the Crossville manufacturing process as new product and no processing waste is sent offsite for disposal. Due to this, diversion table is included.

Equity Petal

15. Ethical Supply Chain

There are no relevant certifications for the combination of location, sector, and issues represented by its top 10 suppliers list. As such, Crossville is incorporating the associated social risks within its supplier code of conduct to ensure its suppliers are keeping these social concerns in consideration.

Beauty Petal

19. Beauty & Spirit Imperative

Retro Active 2.0

Crossville’s RetroActive 2.0 was designed by Michelle Lamb, Michelle Lamb is co-founder and chairman of Minneapolis-based Marketing Directions, Inc. Established in 1987, Marketing Directions specializes in home furnishings color and trend forecasting, working extensively with clients to provide individual direction and color specification. A sampling of past and present clients includes Pier 1 Imports, ACCO, Hunter Douglas, Target Stores, Home Depot, Walmart, Gerber Baby Products, Tarkett, Hunter Fan, 3M, EK Success, Jo-Ann Stores and Petmate. Ms. Lamb was also a founding member of the Sustainable Furniture Council, and she has served on the board of directors of WithIt and Color Marketing Group.

Michelle explains that the design of RetroActive 2.0 was intended to connect people to the colors of the world. From the warmth of Gulf waters and the chill of the Antarctic landmass to lush deciduous forests and raw minerals found in the earth, inspiration for Crossville’s newest Retroactive colors was drawn directly from nature. That’s why these hues feel so comfortable and familiar. Bringing them into decorating palettes forges an instant connection with the natural world, and plays an important role in bringing the outdoors inside.

Shades 2.0

Shades 2.0 from Crossville derives its subtle beauty from nature’s elements. With the second iteration of this highly sought-after line, inspiration is taken from earth and water, resulting in the addition of Midnight – a deep dive into blue – and Russet -evoking rich, bountiful soil. These as well as Shades’ mineral rich warm and cool neutrals, are as foundational as earth itself. In Shade’s patterned tiles, a subtle pattern inspired by the veining system of a leaf reduced to bold and angular graphics, offer even greater creativity options for design.

Shade’s is made in Crossville’s TN plant, known throughout the industry for its recycling of water and fired scrap, making Crossville’s tile manufacturing a highly sustainable process.

Color Blox 2.0

Color Blox 2.0 breathes new life into a longstanding line from America’s must sustainable tile manufacturer. The new colors added to the line are water and plant inspired and bring a sense of nature to interiors. Blue Suede Shoes, and original color, is now complimented with Little Boy Blue, a rich and royal hue. A new brighter green evoking the change of seasons – Spring Sage – refreshes the green offering. Bridging the gap between blue and green are Just Ducky and Celestial Horizon. The clean plaster-inspired graphic allows these natural hues to be the focus of a space.

Color Blox 2.0 is made in Crossville’s TN plant, known throughout the industry for its recycling of water and fired scrap, making Crossville’s tile manufacturing a highly sustainable process.