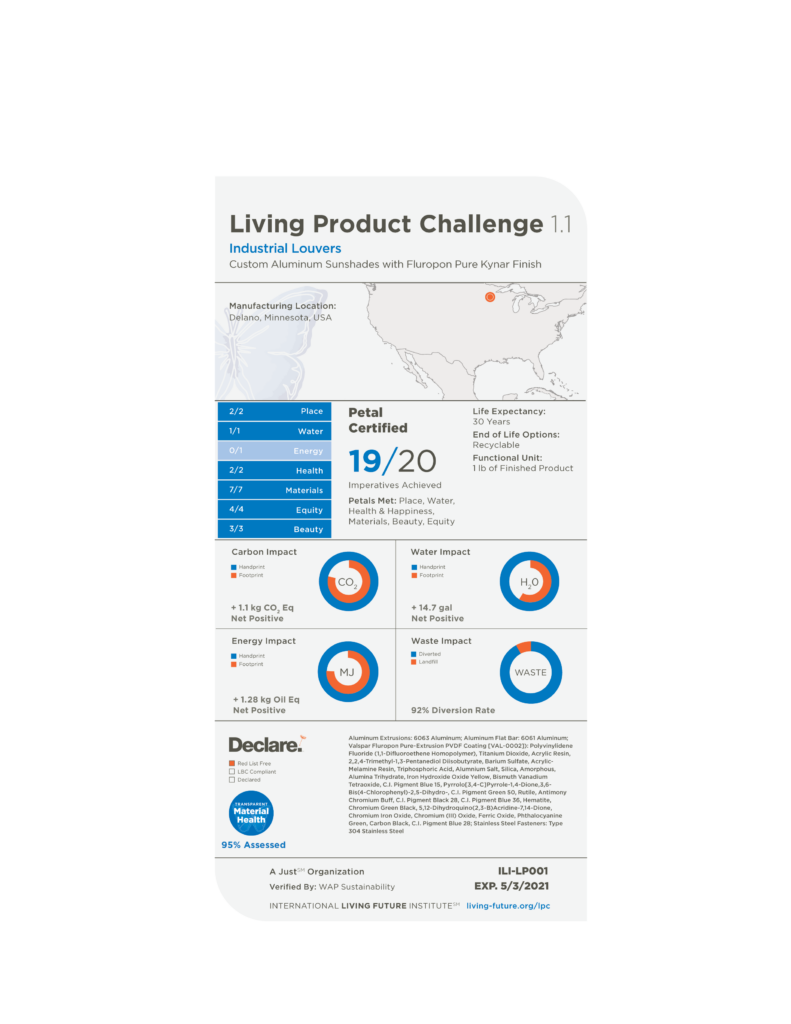

Industrial Louvers, Inc. (ILI) is a customer-focused, woman owned and operated manufacturer of custom architectural metal products including architectural louvers, equipment screens, decorative grilles and sunshades. Its position as a leader in the industry is not only based on its reputation of crafting products of the highest quality and providing unmatched customer service, but also draws from its commitment to sustainability, our employees, and our local community.

Sustainability is central to all that ILI does. It has a commitment to continuous improvement in sustainable operations reduces our company’s environmental impact. ILI also takes great effort to increase awareness about environmental issues within its industry and help create a more sustainable built environment. As ILI’s core values include sustainability and transparency, the Living Product Challenge was a natural fit and way for ILI to illustrate its commitment to these values.

ILI selected the Painted Sunshade products for the Living Product Challenge because their main purpose is to contribute to sustainable designs while contributing to the beauty of a building. Sun control products help reduce energy consumption and increase occupant comfort. Exterior sunshades have a critical impact on cooling and lighting systems and, when used properly, significantly reduce buildings’ energy loads. They also reflect sunlight from buildings to reduce heat island effect and diminish glare, minimizing energy consumption and fostering a more pleasant occupant experience. Informed by nature, like trees they help encourage connection with nature by providing shade without blocking views.

ILI initiated its LPC efforts with the Just label. It offered concrete metrics that employees could understand, allowing the company to clearly and constructively evaluate its performance on a wide variety of issues within the context of equity. By identifying its strengths and weaknesses in these performance areas, ILI was better prepared to evaluate more complex imperatives of LPC. As with the Just label, each Imperative provided opportunities for improvements and further engagement.

| Top Hurdles to Certification | Challenge | Solution/Changes Implemented |

|---|---|---|

| Net Positive Water | The products provide positive handprints in water in a time period much shorter than their warranty. The challenge is that ILI is in the midst of changing the wash and pre-treat process, which will use more water and affect the process of maintaining a net positive impact. Estimates for water use are extremely varied for the new process. | In designing its new facility and new paint line, ILI used a worst case scenario for water use in the facility, and average case scenario for rainwater catchment. At the very least, the system will provide all of the water for the product share of its Painted Sunshades Living Product, approximately 25% of process water, which can then be recycled several times. If the system uses water based on the low range of estimates, or if the facility’s region experiences higher than average rainfall, ILI will be able to harvest rainwater to support 100% of our operation. |

| Red List | Although the product is free of Red List chemicals, ILI uses some items on the Red List in the facility as part of a pretreatment process. | This Imperative provided ILI with an opportunity to completely rethink how it pre-treats products and provided motivation for its suppliers to help ILI in this process. After years of testing, ILI was able to develop a strategy to completely eliminate chrome from its process and become the first completely chrome-free Kynar finisher. ILI believes this is the biggest accomplishment related to the Living Product Challenge. |

| Responsible Industry | FSC Packaging | Although there are several local suppliers of high-quality FSC Certified Wood, the sources for packaging grade wood are extremely limited, and conversion to FSC Certified Wood would have represented a nearly 25% increase in total packaging costs. ILI will balance purchases for the performance year with either FSC or SFI Certified Wood for the product share of the Living Product and continue to search for sources that will allow the company to improve packaging practices for all of its products. |

| Equitable Product Access | Affordable housing designs do not incorporate aluminum extruded sunshades in general. The size, structure and weight of the products and the all-metal look are not usually congruent with the design strategies used in affordable housing. This provides a significant barrier – the products do not typically make sense and are not currently specified in current affordable housing designs. This significantly limits opportunities to engage in affordable housing projects. | ILI was awarded an exemption for this Imperative, but maintains its support for affordable housing through participation in the Healthy Affordable Materials Project (HAMP). |

| Beauty and Spirit | The challenge for this Imperative was not related to changing ILI’s product or materials, but instead changing the way it thinks about them. | ILI’s products are informed by the natural world, as trees provide shade, and so do its sunshades. Having changed perspective, ILI can incorporate more nature-inspired design for new products. |

3-YEAR PLAN

ILI’s painted sunshades achieve Net Positive impacts for water, energy and climate impact categories well within their warranty period. ILI is developing a plan to incorporate on-site renewable energy and purchase carbon offsets prior to the end of the performance period of its Living Product as part of its 3-Year Plan.

PLACE PETAL

01. RESPONSIBLE PLACE AND HABITATS IMPERATIVE

ILI produces and finishes products in one location in Delano, Minnesota. The land at this location belongs to the near-arctic ecoregion, the temperate broadleaf and mixed forests biome, and is part of the Upper Midwest Forest/Savanna Transition Zone (UMTZ), the smallest of three ecotonal units along the Great Plains. With less than 5% of the land intact, the UMTZ is listed under Critical/Endangered status, though most land depletion occurred during the first half of the 1800s. The property was not a greenfield when ILI acquired it in the late 1960s. Various portions of the land were once used as cultivated farmland, residential dwellings, and an egg processing business, all of which were converted to their current function over the period from 1967 to 2007.

Today, most animal species remain because they are generalists, but deer overpopulation and disproportionate populations of small predators threaten balance in the region. Using data from the US Fish & Wildlife Service, in conjunction with the IUCN Red List of Threatened Species, ILI identified three endangered species that are found in the same region as ILI: Bombus affinis (the rusty patched bumble bee), Plethobasus cyphus (sheepnose), and Myotis sepentrionalis (northern long-eared bat). Additionally, ILI found that the Hesperia dacotae (Dakota skipper) is found in Minnesota, but IUCN mapping data did not indicate if it was found in the region.

In an effort to better incorporate the site into its surroundings, ILI has planted a garden of native wildflowers to contribute to regeneration of the local ecosystem.

02. HABITAT EXCHANGE IMPERATIVE

Minnesota’s prairies are in crisis. Only 1% of its original prairie remains due to conversion to agriculture and development. The area in which ILI is located is home to four endangered species that depend on this type of habitat. The Nature Conservancy’s mission, “to conserve the lands and waters on which all life depends” is directly related to restoring this type of habitat in this region. One of the projects supported with ILI’s donation is the Shaefer Prairie Reserve, located 45 minutes from ILI’s facility. The preserve is home to approximately 275 plant species, of which 245 are native to Minnesota. Through seed collection, planned burning and replanting, as well as removing invasive plant species, the Nature Conservancy and volunteers are methodically restoring the 160 acre preserve. The preserve is also open to the public and is used as an outdoor classroom to help educate children, college students and the surrounding communities on the importance of native habitat.

The Nature Conservancy is a Certified Land Trust.

| Name of Habitat Exchange Project | Schaefer Prairie Restoration |

| Name of Participating Land Trust: | The Nature Conservancy |

| Land Trust Website: | https://www.nature.org/ourinitiatives/regions/northamerica/unitedstates/minnesota/index.htm |

PLACE PETAL LESSONS LEARNED

ILI realized it can positively impact the habitat around its facility more than it anticipated. Although its land was developed long before it acquired the site, there are things all companies in similar situations can do to make it better. Effective planting of native plants and contributing to land trusts can help them in this process.

WATER PETAL

03. NET POSITIVE WATER IMPERATIVE

ILI’s painted sunshades achieve a Handprint larger than their footprint in an average of 3.9 years. This calculation is based on LCA calculations combined with average annual energy savings studies. Greg Norris, ILFI’s Chief Scientist performed ILI’s LCA and corresponding Handprinting offset study.

Water consumption within the cradle-to-gate system for manufacturing the painted sunshade is associated with a variety of processes, most of which are related to the generation of electricity. The extrusion of the aluminum and production of aluminum from secondary scrap also make significant contributions. The contribution due to production of “water, decarbonized, at plant” was investigated, and appears to be present at low levels across the supply chains of many of the inputs, rather than being dominant within the supply chain of any one input.

Handprinting payback was based on a study by John Carmody and Kerry Hagulund at the Center for Sustainable Building Research at the University of Minnesota. The simulation quantified the extent to which two sizes of sunshades (shallow or deep) as well as unshaded control case effect energy in a variety of glazing types. Annual inputs were simulated for south, east and west facing windows in six U.S. cities using unique inputs for each climate and orientation.

ILI’s onsite contributions to overall water use will increase with the development of a new paint process. To offset this increase on site, ILI is installing a rain water catchment system. New process water estimates are imprecise, so ILI implemented a plan based on the worst case scenario. ILI’s site is based in Delano, MN, which receives an average annual rainfall of 24.2 inches of rainfall between April and October. Approximately 60% of all rain events are 0.5” of rain or less, and approximately 90% of rain events are less than 1” of rain. ILI planned a storage system so that if 1” of rain is captured from the catchment area, it will fill completely if it is empty at the time of the rain event. Overflow would occur if more than 1” of rain fell, or if the tank was not empty. With this system, ILI can offset the entire water share for its painted sunshades, and possibly its entire operation.

| Water consumption per functional unit: | 30.47 cubic meters |

| On-site annual water use: | 1.06% of total annual water use |

| LCA Functional Unit: | One typical section, a 227.329 lb unit |

| LCA Result: | Water payback occurs in an average of 3.4 years |

| Water Hotspots | Description |

|---|---|

| Aluminum Input | Harvest and production of primary aluminum |

| Extrusion of aluminum | Processing of secondary scrap aluminum |

| Electricity input | Electricity to support manufacturing of extrusions |

| Transportation and other | Transporting product and all remaining uses |

HEALTH & HAPPINESS PETAL

Building occupants need access to light and views because interaction with nature makes occupants happier, healthier and more productive. Sunshades allow people in a building to enjoy views of nature like those sitting outside under a tree. Sunshades, like trees, provide relief from excess heat and glare without blocking the view to the outdoors. Outriggers, like branches, support the blades that provide the shade.

ILI recognizes that the employees that manufacture its products that allow comfortable access to nature also deserve that same connection while they are working. ILI also wants to empower its employees to lead healthy lifestyles. As a result, ILI is transforming its manufacturing facility to provide access to daylight and views throughout the work day. New skylights provide natural light, and windows provide views to the outdoors. This is particularly important during the short days of cold Minnesota winters, when daytime employees would not otherwise be outdoors during daylight hours.

ILI designs the products to be safe for human and environmental health by ensuring minimal waste during the manufacturing process, supporting transparency by reporting all materials in its products and optimizing its products to eliminate chemicals of concern. The LPC provided ILI with an opportunity to completely rethink how it pre-treats products and provided motivation for its suppliers to help ILI in this process. After years of testing, ILI was able to develop a strategy to completely eliminate chrome from its process and become the first completely chrome-free Kynar finisher. ILI believes this is biggest accomplishment related to the LPC.

05. TRANSPARENT MATERIAL HEALTH IMPERATIVE

Transparency of operations is one of ILI’s core values, so creating a material health inventory for its products was a high priority for the organization. ILI worked closely with its suppliers to create Health Product Declarations (HPDs) for several product lines including the painted sunshades Living Product. ILI’s reports include the name, CAS number, % of content, role and associated hazards of each ingredient as identified in the GreenScreen List Translator platform. WAP Sustainability provided a third-party verification of the HPDs and Declare Labels informed by the same. Aluminum, the primary ingredient in ILI’s products, underwent a Material Health Assessment to ensure compliance with the Living Product Challenge Material Health Requirements.

ILI also cares deeply for the safety and welfare of its employees. ILI also provided a list and corresponding SDS reports for all of the materials included in the manufacturing process which are not included in the final product. ILI is very proud that it was able to develop a strategy to completely eliminate chrome from its process and become the first completely chrome-free Kynar finisher. ILI believes this is biggest accomplishment related to the LPC.

06. HUMAN THRIVING IMPERATIVE

In the natural world, people seek out the shade of trees for a break from the sun’s glare and heat. In the shade of a tree, one can relax and enjoy the benefits of the natural beauty of the outdoors while remaining comfortable. Sunshades provide the same protection for building occupants.

Building occupants need access to light and views because interaction with nature makes us happier, healthier and more productive. Sunshades allow people in a building to enjoy views of nature like those sitting outside under a tree. Sunshades, like trees, provide relief from excess heat and glare without blocking the view to the outdoors. Outriggers, like branches, support the blades that provide the shade.

ILI recognizes that its employees that manufacture products that allow comfortable access to nature also deserve that same connection while they are working. ILI also wants to empower its employees to lead healthy lifestyles. ILI is transforming its manufacturing facility to provide access to daylight and views throughout the work day. New skylights provide natural light, and windows provide views to the outdoors. This is particularly important during the short days of cold Minnesota winters, when daytime employees would not otherwise be outdoors during daylight hours.

ILI offers a variety of amenities and programs in pursuit of encouraging healthy lifestyles. To improve the human/nature connection, the facility features an employee garden and outdoor picnic tables, and ILI encourages employees to take advantage of the walking trails in the local area surrounding the facilities. For cold and rainy weather days, there are treadmills and ping pong and pool tables. When possible, ILI gives employees the option to conduct walking meetings outdoors rather than meeting in the conference room. Finally, ILI offers every employee a $50 grant toward a race or athletic activity and discounts their gym memberships through its insurance policy.

HEALTH & HAPPINESS PETAL LESSONS LEARNED

ILI administered a survey to determine if employees were taking advantage of the resources it currently offers and what improvements it could make. ILI found that several resources, especially picnic tables, were heavily used.

Employees also provided suggestions for programs that ILI could implement that would help them be more active and better connect with nature. People requested bike racks, rental bikes, outdoor meetings, horseshoes or a basketball hoop, morning yoga sessions, showers at work (so employees can run at lunch), a walking club, various challenges (biggest loser, healthy eating challenges), group fitness classes, a quiet outdoor reading place, and an employee cookbook with healthy recipes. ILI is evaluating which of these can be incorporated into its wellness program.

ILI is currently building a major addition to its facility that will be completed in a series of phases. A central consideration throughout the planning process has been improving the building’s natural light, airflow, outdoor spaces, and athletic resources, all of which will help ILI better meet the intent of this Petal. The new building will provide employees with more open, collaborative workspaces and better access to natural light. ILI will have an improved workout area with lockers and showers, which will allow employees to have more flexible workout schedules.

MATERIALS PETAL

07. RED LIST IMPERATIVE

Transparency of operations is one of ILI’s core values and so creating a material health inventory for its products was a high priority for the organization. ILI worked closely with its suppliers to create Health Product Declarations (HPDs) for several product lines including the painted sunshades Living Product. ILI’s reports include the name, CAS number, % of content, role and associated hazards of each ingredient as identified in the GreenScreen List Translator platform. WAP Sustainability provided a third party verification of the HPDs and Declare Labels informed by the same. Aluminum, the primary ingredient in ILI’s products, underwent a Material Health Assessment to ensure compliance with the Living Product Challenge Material Health Requirements.

We support efforts to create a healthy materials economy by providing training for our suppliers in understanding and producing HPDs and request chemical information from all potential suppliers. This information is used in selecting suppliers.

08. LIVING ECONOMY SOURCING IMPERATIVE

FINAL PERCENT OF TOTAL BUDGET SOURCED FROM EACH ZONE:

| <1000 km | 68.39% |

| <2000 km | 10.89% |

| <5000 km | Small percentage of the remaining purchases |

09. RESPONSIBLE INDUSTRY IMPERATIVE

ILI is committed to producing, sourcing, and supporting products that maximize social good, ethical practices, and environmental sustainability. Its mission is to make the world better with every product it sells by purchasing and producing materials and products that not only avoid harm, but actually benefit communities and the environment.

ILI conducted an extensive vendor survey about potential suppliers’ sustainability goals and practices, prioritizing business with firms whose values align with its own. Unfortunately, the majority of the manufacturing sector is still behind in regards to sustainability. Oftentimes, it is impossible to avoid business with organizations who do not share a sustainable organization’s vision. ILI’s goal is to shift the industry with its accomplishments of producing net positive products and encouraging others to follow suit.

In 2018, ILI has committed to purchasing FSC wood in amounts proportional to the product share of its painted sunshades. If ILI is unable to source FSC wood, it will purchase SFI wood instead. These purchases will be verified by WAP during the annual audit following initial certification.

10. NET POSITIVE CLIMATE IMPERATIVE

Though this Imperative was initially thought to be out of scope, subsequent analysis of the LCA model showed that the product is already Net Positive for climate impact across the product life cycle.

12. PRODUCT FIT TO USE IMPERATIVE

ILI’s sunshades are designed to contribute to the beauty and function of a building throughout the building’s entire life cycle. The sunshade begins to create a positive handprint for water, energy and climate in hot climates as quickly as two years, and in cold climates in no more than 16 years. In every case, the sunshade creates handprints well within the warranty period. Painted sunshades installed in the mid-1990s still look beautiful and have provided Handprints many times their footprints.

Painted sunshades are external building features, so the largest potential factor for failure is the product’s finish. High performance coatings have to stand up against weather extremes. As such, ILI uses Valspar’s Fluropon Pure coatings that meet or exceed AAMA 2605 and carry a 20-year warranty (attached). Fluropon Pure coatings also offer opportunities to comply with Red List Free requirements for Living Building Challenge projects.

13. USEFUL LIFE DISPOSAL IMPERATIVE

ILI produces sunshades intended to last for the life of the buildings on which they are installed. At the end of a building’s life, or if a major building remodel includes replacing product, the sunshades can be removed, disassembled and recycled.

As a structural design element generally installed high on a building, they are not labeled for recycling in the way that consumer goods are marked. Upon completion of each project, ILI provides detailed drawings indicating how the product was assembled, type and location of all fasteners and alloy of each of the aluminum extrusions in the construction. These drawings are provided to owners as part of the as-built drawings for project and can aid in deconstruction. If drawings are misplaced or unavailable at deconstruction, aluminum extrusions are easy to identify by their physical properties. The mechanically fastened construction ensures that sunshades can be easily disassembled.

Aluminum and other nonferrous metals can be recycled effectively with minimal degradation of their physical properties. According to the Institute of scrap Recycling Industries, Inc. (ISRI), nonferrous metal scrap, including aluminum, accounts for approximately seven percent of total quantity of recycled material in the United States, but more than half of the scrap recycling industry earnings. The significant value of scrap aluminum helps ensure that it will be recycled and continue to be part of the nonferrous metals life cycle.

Demolition teams are generally familiar with locations of scrap recyclers. ILI also provides links to a database of nonferrous metal recycling facilities on our website at www.industriallouvers.com/sustainability.

INNOVATIONS RESULTING FROM THE MATERIALS PETAL

The LPC provided ILI with an opportunity to completely rethink how it pre-treats products and provided motivation for its suppliers to help ILI in this process. After years of testing, ILI was able to develop a strategy to completely eliminate chrome from its process and become the first completely chrome-free Kynar finisher. ILI believes this is the biggest accomplishment related to the LPC.

EQUITY PETAL

14. EQUITABLE PRODUCT ACCESS IMPERATIVE

ILI’s sunshade products are generally used on commercial and institutional buildings. They are not commonly used in housing of any type, and so ILI does not actively market in the single family or multi family housing markets.

In learning of its positive handprint, ILI identified potential to positively impact affordable housing projects through the use of its products, mainly in the form of energy savings and healthy materials. Lisa Britton, ILI’s Director of Sales & Marketing/Sustainability Champion, serves on the Healthy Affordable Materials Project (HAMP) advisory committee. The Healthy Affordable Materials Project seeks to improve the lives and health of affordable housing residents by reducing the use of toxic materials in building products.

An exception was granted to Industrial Louvers because the products are not sold in residential markets.

15. RESPONSIBLE CO-PRODUCTS IMPERATIVE

For over 15 years, transparency has been one of our core values. Transparency about ILI’s operations, including business practices, management, finance, and product ingredients demonstrates respect for its employees and communities and is essential to treating them ethically. ILI supports transparency through its business relationships by conducting a thorough survey of its vendors about their practices, materials, and values. ILI remains committed to ensuring that it does not make, sell or provide any of the goods and services referenced in I15 Responsible Co-Products.

16. EQUITABLE INVESTMENT IMPERATIVE

ILI strives to support local charities and those that are important to our employees. In addition to its donation to The Nature Conservancy toward the requirements of Imperative 02 Habitat Exchange, ILI donated almost 8000 USD to local Delano-based charities through a combination of company-sponsored events and donations and employee-driven donations.

As an organization, we use Red Nose Day both as an opportunity to support ending child poverty and as an opportunity to build camaraderie and have fun. The company also supported the Disabled American Veterans and the Minnesota Ovarian Cancer Alliance.

As part of its effort to build a culture of giving, ILI provides every employee the opportunity to donate 100 USD to a charity of their choice. Through that program, ILI has supported a wide range of groups including the Cub Scouts, the local volunteer fire department, community sports teams and a benefit for a relative of one of its employees. This program has helped prompt employee-organized events throughout the year that are not included in monetary calculations including a coat and blanket drive, school supply drive and several food drives.

17. JUST ORGANIZATIONS IMPERATIVE

JUST helped ILI focus its goals and showed the organization that it has the tools to promote equity and social justice. The program made corporate sustainability a more measurable goal by breaking it into a series of indicators and providing several metrics by which to evaluate its success. The process was affirming because it showed ILI that, in many ways,the company is already a positive entity for driving equity and community well-being. It also helped ILI develop strategies for improvement on some indicators.

Throughout this process, ILI was reminded that it is situated in local and industry-specific contexts that make its capacity to address JUST metrics and achieve its goals unique. As a firm with a single location, ILI saw great success in the Local Benefit indicator. ILI realized that it plays an integral role in building the local community and saw how various company policies can be utilized and expanded to maximize the positive outcomes of that connection.

ILI also faced some exceptional challenges. For example, because sheet metal fabrication is an industry dominated almost 100% by men, ILI found that it would be next to impossible for any similar manufacturing firm to achieve a 50/50 gender divide at this moment in time. ILI is the only woman owned business in the industry and boasts an executive leadership team dominated by women. While frustrating, it conveyed the most important lesson an organization could learn from the program: JUST is simply a starting point. It is a platform for evaluating an organization’s contributions to corporate social responsibility and developing strategies to achieve its goals, but it is also useful for understanding what goals deserve the closest attention and what changes it should advocate at a larger scale – in the industry and in society – before organizations can achieve them as an individual company.

BEAUTY PETAL

18. POSITIVE HANDPRINTING IMPERATIVE

ILI’s painted sunshades achieve a water handprint larger than their footprint on average in less than 3.9 years, an energy handprint larger than their footprint in 5.0 years, and a climate handprint larger than their footprint in 5.2 years. The longest payback for any scenario is less than the 20 year finish warranty. These estimates are based on LCA calculations combined with average annual energy savings studies. Greg Norris, ILFI’s Chief Scientist performed ILI’s LCA and corresponding handprinting offsets.

Water consumption within the cradle-to-gate system for manufacturing the painted sunshade is associated with a variety of processes, most of which are related to the generation of electricity. The extrusion of the aluminum and production of aluminum from secondary scrap also make significant contributions. The contribution due to production of “water, decarbonized, at plant” was investigated, and appears to be present at low levels across the supply chains of many of the inputs, rather than being dominant within the supply chain of any one input.

Handprinting payback was based on a study by John Carmody and Kerry Hagulund at the Center for Sustainable building Research at the University of Minnesota. The simulation quantified the extent to which two sizes of sunshades (shallow or deep) as well as unshaded control case effect energy in a variety of glazing types. Annual inputs were simulated for south, east and west facing windows in six U.S. cities using unique inputs for each climate and orientation.

19. BEAUTY + SPIRIT IMPERATIVE

In the natural world, people seek out the shade of trees for a break from the sun’s glare and heat. In the shade of a tree, one can relax and enjoy the benefits of the natural beauty of the outdoors while remaining comfortable. Sunshades provide the same protection for building occupants.

Building occupants need access to light and views because interaction with nature makes us happier, healthier and more productive. Sunshades allow people in a building to enjoy views of nature like those sitting outside under a tree. Sunshades, like trees, provide relief from excess heat and glare without blocking the view to the outdoors. Outriggers, like branches, support the blades that provide the shade.

In order to support the Beauty + Spirit Imperative, ILI surveyed members of the A&D community for feed back. The survey asked them if they felt ILI’s products include design features intended solely for human delight and the celebration of culture and spirit appropriate to its function. The product must be artfully designed and pleasing to use. ILI also provided the list of requirements for the imperative and asked the following:

- Do you think the product meets the requirements of the imperative? (yes or no)

- Do you think that the product is inspired by nature? (yes or no)

- What kinds of projects do you think would benefit from this type of product?

- Do you think the product enhances the aesthetic qualities of the space? (yes or no)

- What other nature inspired design aspects would you like us to explore?

ILI was very pleased with the responses it received. Respondents indicated that they felt ILI’s products met the intent of the Imperative. They also provided ideas about how ILI could further inform its products through nature.

20. INSPIRATION AND EDUCATION IMPERATIVE

LPC PAGE URL: HTTP://WWW.INDUSTRIALLOUVERS.COM/SUSTAINABILITY/LIVING-PRODUCT-CHALLENGE/

The challenge for this Imperative was not related to changing the products, but instead changing the way ILI thinks about them. Its products are informed by the natural world, as trees provide shade, and so do its sunshades. Now that ILI has changed its perspective, it can incorporate more nature inspired design for new products.

SUMMARY OF PROCESS AND BENEFIT OF PURSUING LIVING PRODUCT CHALLENGE

At ILI, sustainability is central to what we do. ILI’s commitment to continuous improvement in sustainable operations reduces the company’s environmental impact. ILI also takes great effort to increase awareness about environmental issues within its industry and help create a more sustainable built environment. As ILI’s core values include sustainability and transparency, the Living Product Challenge was a natural fit and a way for the company to illustrate its commitment to these values.

ILI selected its painted sunshade products because their main purpose is to contribute to sustainable designs while contributing to the beauty of a building. Sun control products help reduce energy consumption and increase occupant comfort. Exterior sunshades have a critical impact on cooling and lighting systems and, when used properly, significantly reduce buildings’ energy loads. They also reflect sunlight from buildings to reduce heat island effect and diminish glare, minimizing energy consumption and fostering a more pleasant occupant experience. Informed by nature, like trees they help encourage connection with nature by providing shade without blocking views.

ILI began its LPC efforts with the Just label because it offered concrete metrics that its employees could understand, allowing ILI to clearly and constructively evaluate its performance on a wide variety of issues within the context of equity. By identifying its strengths and weaknesses in this performance area, ILI was better prepared to evaluate the more complex imperatives of the LPC. As with the Just label, each imperative provided opportunities for improvements and further engagement.