Superior Essex International LP is an industry leader in the manufacture of optical fiber and copper communications cable products and accessories used to interconnect enterprises, campuses, and communities worldwide. Product lines include Premises and Outside Plant (OSP) copper and fiber data cables, Wireless and Distributed Antenna Systems (DAS) coaxial cables and accessories, and Fire Alarm and Security (FAS) cables. With over eighty years serving the communications industry and related distribution markets, our legacy demonstrates our commitments to producing high-quality products and providing reliable customer service. As a critical component of our business, we strive to ensure our operations are conducted in a safe and environmentally responsible manner, and through these efforts, to make a positive change in the industries and communities we serve.

Superior Essex believes in the International Living Future Institute’s mission and vision of a world that is socially just, culturally rich, and ecologically restorative. With products that are produced and deployed around the globe, Superior Essex is committed to understanding how those products interact with human health and the environment, and ensuring that those interactions are positive. Superior Essex remains dedicated to these efforts by recognizing the value sustainability brings to the customers, industries and communities it serves, because SUPERIOR ESSEX OPERATES WITH AN UNDERSTANDING THAT THE PRODUCTS WHICH INTERCONNECT THE WORLD MUST ALSO RESPECT IT.

Superior Essex chose to pursue LPC certification to further demonstrate its commitment to this vision as well as product transparency, and continuing to foster sustainable manufacturing practices and product development within the cabling industry. LPC certification is a means by which Superior Essex can be more involved in the green building community and explore new business opportunities in this market space. Superior Essex wanted to achieve Living Product Challenge certification to validate its leading sustainability practices, as the standard itself is ultimately an assessment of the sustainability program to date.

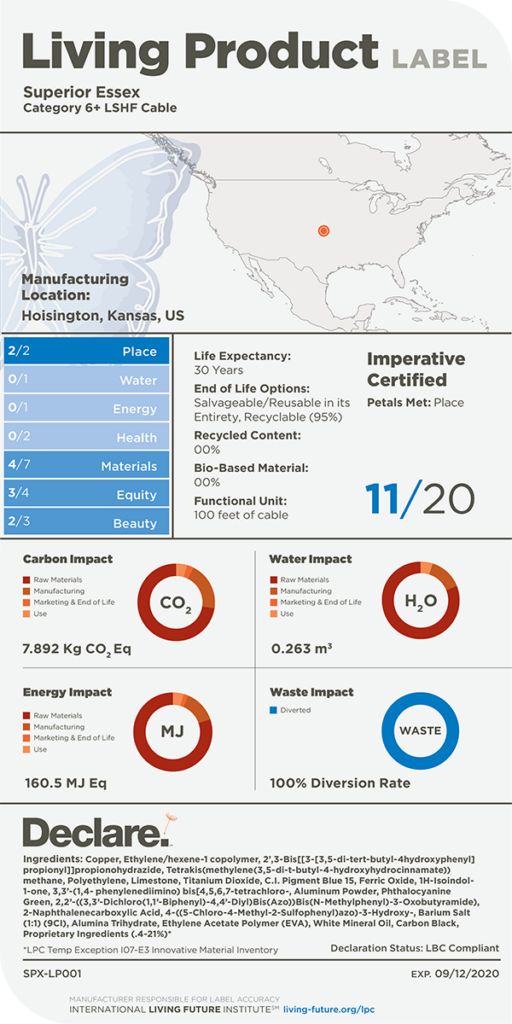

The product that has achieved LPC certification is the CATEGORY 6+ LOW SMOKE HALOGEN FREE COPPER COMMUNICATIONS CABLE. This product is primarily used as a means of transmitting communications throughout the built environment. It is the first product of its type to be completely free of Red List ingredients and to receive UL’s Low Smoke Halogen Free designation. It is also the first product of its type to be manufactured in a Zero Waste to Landfill Certified facility, and to offer Environmental Product Declarations and Health Product Declarations that disclose the environmental and health impacts of its material ingredients and manufacturing process.

Achieving certification for this product required rigorous investigation into, and detailed reporting of, the material compounds that make up each component of the final product, from the copper core to the outer jacketing.

While Superior Essex has not yet pursued Imperatives that require Handprinting efforts, we are nonetheless considering how to further reduce our footprint and are exploring how to engage in Handprinting actions.

In the coming year, Superior Essex will update its life cycle assessment models and environmental product declarations. It will also conduct an analysis of reduction efforts over the past four years, which have driven total reduction in life cycle impacts of its products and operations. Superior Essex’s Digital Building and IoT technology/products provide up to 75% energy savings (pending the scenario), so the goal is to educate the marketplace on this new technology and use this product as a platform to assess the potential for future Handprinting opportunities.

TOP HURDLES TO CERTIFICATION

| Top Hurdles to Certification | Description of Solution/Changes Implemented |

| 1. New Product Development | Development Created new product that met LBC Red List Free standards. |

| 2. Supply Chain Communication | Worked with supply chain to collect the appropriate disclosure information to meet LPC requirements. It took over 1.5 years to collect this information. |

| 3. Marketing | With personnel departures and travel schedules, marketing efforts have been delayed, but Superior Essex plans to increase this and have LPC be one of the main messages it brings to the market place in 2018 by all of its sales representatives. |

PLACE PETAL

01. RESPONSIBLE PLACE AND HABITAT IMPACTS IMPERATIVE

The Superior Essex Hoisington manufacturing facility, located in Hoisington, Kansas, is located in the Central Grassland region, which features a variety of ecosystems including temperate grasslands, savannas and shrub lands, and harbors several endangered species of flora and bees. Originally built in 1974 to produce copper wire and cable, the facility has gradually expanded its production capacity to include a variety of copper communications cables. Several measures were taken to ensure the facility has a limited environmental impact on the surrounding environment. These include implementing a closed-loop water system that recycles or reuses 100% of the water required during the extrusion process, as well as robust materials recycling and waste diversion programs that ensure >98% of the waste created during manufacturing is either recycled or reused. As a result of these efforts, the Hoisington facility became the first Zero Waste to Landfill Certified cable manufacturing facility in 2015 (as certified by Green Circle Certified), and continues to maintain that status today.

02. HABITAT EXCHANGE IMPERATIVE

Superior Essex chose to donate a percentage of all sales of the Cat 6+ LSHF product to 1% for the Planet. This organization seeks to support environmental solutions by providing financial donations, volunteer time, in-kind donations, and other shared-value collaborations between businesses and individuals. Superior Essex chose this organization because of its wide area of impact and its large network of individuals, non-profits and private enterprises that are collaborating to make positive change.

Name of Habitat Exchange Project: 1% FOR THE PLANET

Website: https://www.onepercentfortheplanet.org/what-we-do/our-approach

PLACE PETAL APPEALS AND LESSONS LEARNED

One of the main mottos of 1% for the Planet is “Do more together than you can alone.” Superior Essex aligns greatly with this; as a whole, we have so much more potential to reduce our impacts that we can accomplish individually. Superior Essex wanted to support an organization with these values and take a step toward collective betterment.

MATERIALS PETAL

The process to achieving material transparency for the CAT 6+ LSHF product began several years ago when Superior Essex first began to pursue product transparency reports such as Environmental Product Declarations and Health Product Declarations. Superior Essex took this opportunity to not only disclose the material ingredients of its products, but to also evaluate the environmental and health impacts of these material ingredients. As a result of these evaluations, Superior Essex was able to research innovative materials free of Red List ingredients to use in its products that are significantly less harmful to people and the environment throughout the product’s life cycle, from manufacturing and deployment through end-of-life practices. Ultimately, the goal was to change the way communications cable was designed and manufactured, and prove to the company’s competitors and customers that environmentally-friendly cable products free of Red List ingredients were not just a possibility, but a priority for the future.

This was a difficult process due to the myriad material ingredients that comprise a cable product. The materials optimization process was made more complex by the supply chain of certain plastic materials used in the jacketing. While many suppliers were able to accommodate the material reporting requirements, one supplier could not due to patented, protected information about those materials. However, by working closely with that supplier, Superior Essex was able to determine that, although the materials could not be fully disclosed, they were free of Red List ingredients, maintained a limited environmental impact, and met the criteria for the Living Product Challenge. The supplier then also obtained a Platinum Cradle to Cradle Material Health Certificate to further demonstrate that the materials were optimized through request of Superior Essex.

07. RED LIST IMPERATIVE

Superior Essex has been committed to product transparency for several years, during which time our products have undergone extensive reviews and assessments of the material ingredients, their health and environmental impacts, including full Life Cycle Assessments for copper and optical fiber cables, and transparency of the compositional chemistry of these products and reporting with Health Product Declarations.

Because Superior Essex was the first in its industry to complete these evaluations, many of these processes involved had to be created and vetted by third-party consultants and standards bodies. The goal of these evaluations and disclosures was two-fold. First, Superior Essex wanted to be transparent about what goes into its products. Second, the company wanted to make its products healthier for the end user and better for the environment as a whole. As a result of these efforts, Superior Essex was the first cable manufacturer to publish Environmental Product Declarations and Health Product Declarations for over fifty copper and optical fiber communications cables. It was also the first in its industry to produce a cable product free of Red List ingredients. These new products required entirely new materials innovations for cable jacketing, which were created and tested at Superior Essex’s Product Development Center.

09. RESPONSIBLE INDUSTRY IMPERATIVE

Due to issues of proprietary supply chain information, Superior Essex was unable to meet the reporting requirements of the Declare program and was not awarded a label. However, Superior Essex was still able to pursue LPC because it met the intent of the program and demonstrated that the single proprietary innovative material was optimized by Cradle to Cradle Platinum certification of the jacket material. On an annual basis following certification, Superior Essex will continue to monitor and reassess additional supplier options or whether the existing supplier (PolyOne) is willing to disclose additional information, in order to obtain levels of transparency required for the LPC program. Superior Essex will also continue to communicate to the supplier (PolyOne) that it continues to seek additional disclosure and will also seek other suppliers willing to provide additional disclosure.

11. NET POSITIVE WASTE IMPERATIVE

Superior Essex is proud to be the first cable manufacturer to earn Zero Waste to Landfill certification, as certified by GreenCircle Certified, LLC. The journey to zero waste status took nine years, and required several wholesale manufacturing changes within the company. A true zero waste facility accounts for the potential waste created throughout its entire downstream process, including that of third-parties that are involved in the recycling and reuse of waste materials. For Superior Essex, this means continuing to ensure that the companies it uses to recycle scrap metals, wood, plastics and other materials are not sending waste by-products to landfill. One example is how Superior Essex handled the recycling of plastic waste that is created in many different manufacturing operations. A decade ago, most of this plastic waste was sent to a landfill. Today, each variety of plastic waste is kept separated on-site and is re-processed downstream into new plastic pellets that can be blended with virgin plastic for new cable production or used for other non-cable product purposes.

Since 2015, Superior Essex has maintained its Zero Waste to Landfill status, for three consecutive years, diverting over 13.5 million pounds of waste from landfills. Superior Essex has also reduced its manufacturing waste by 16% since 2011, and has continued to reduce certain types of manufacturing waste such as scrap FEP (fluorinated ethylene propylene) wire and reprocessed FEP waste by 12.27% and 6.05% by weight, respectively, which has contributed to an overall environmental impact reduction of the company’s operations.

Final percentage and amount diverted from landfill: 100%, 13.5 MILLION POUNDS OVER 3 YEARS

12. PRODUCT FIT TO USE IMPERATIVE

Superior Essex cable products are deployed across the world in a variety of environments, and many of these products maintain a decades-long life cycle. For this reason, Superior Essex is committed to ensuring that these products are designed, tested and warrantied to last in every type of installation. To meet this commitment, Superior Essex cables include the most innovative material components designed for durability, undergo rigorous in-house testing as well as third-party testing and certification, and are warrantied for the full life of the product.

With respect to product design, each Superior Essex cable product utilizes innovative material components that ensure the product will not degrade during its useful life. This includes components within the cable core such as fillers, insulators, buffers and dividers, as well as exterior components such as jacketing and armors.

Each cable product is rigorously tested by a team of engineers at Superior Essex’s Product Development Center. Testing parameters include everything from electrical performance to dynamic weathering over varying periods of time. This ensures that every product meets industry-standard and customer-specific performance requirements and that they are ready for installation well before they reach the customer. Following in-house testing, Superior Essex submits each product to third parties such as UL for additional testing and certification.

Finally, Superior Essex backs the quality and durability of its products throughout their lifecycles with industry-leading warranties ranging from 20 to 40 years.

13. USEFUL LIFE DISPOSAL IMPERATIVE

Superior Essex is continually committed to reduce waste to landfill at not only our manufacturing facilities but also in the marketplace as a whole. Superior Essex has the ability to take back our CAT 6+ LSHF product that is excess, scrap and/or at the end of its life throughout the United States. This product can be scrapped for its materials, some of which can then be recycled and/or reused in the production of new materials or products.

Superior Essex also participates in the EcoReel Recycling Program through Sonoco. This program allows its manufacturing facilities as well as its customers to send any wooden reels used to hold Superior Essex product to Sonoco to be refurbished and reused in new cable product deployments.

EQUITY PETAL

14. EQUITABLE PRODUCT ACCESS IMPERATIVE13. USEFUL LIFE DISPOSAL IMPERATIVE

Superior Essex is a proud supporter of affordable housing initiatives and frequently participates in the donation of product to low incoming housing projects such as those created by Habitat for Humanity. As a part of its commitment to this initiative, Superior Essex is willing to provide discounted or free Cat 6 LSHF product to affordable housing projects per the International Living Future Institute’s Affordable Housing Initiatives.

15. RESPONSIBLE CO-PRODUCTS IMPERATIVE

Superior Essex is owned by LS Cable, a Korea-based organization established in 1962. LS Cable owns multiple entities, including Superior Essex Inc. Superior Essex International LP-Communications is the branch in which Superior Essex manufactures and sells the CAT 6 LSHF product out of the Hoisington, KS facility. Superior Essex International LP-Communications and its subsidiaries confirm that they do not make, sell, or provide any of the goods and services proscribed in the 1.1 LPC Standard.

16. EQUITABLE INVESTMENT

Superior Essex has chosen to donate a percentage of all sales of the Cat 6+ LSHF product to 1% for the Planet. This organization seeks to support environmental solutions by providing financial donations, volunteer time, in-kind donations, and other shared-value collaborations between businesses and individuals. Superior Essex chose this organization because of its wide area of impact and its large network of individuals, non-profits and private enterprises that are collaborating to make positive change.

The donation is expected to increase as sales of the Cat 6+ LSHF product increase over the next several years; Superior Essex looks forward to continuing to donate to this cause in the coming years.

Name of charitable organization receiving equity investment: 1% FOR THE PLANET

Website: https://www.onepercentfortheplanet.org/what-we-do/our-approach

BEAUTY PETAL

19. BEAUTY + SPIRIT IMPERATIVE

Superior Essex communications cable products are used to connect people, enterprises, campuses and communities worldwide. With products that are produced and deployed around the globe, Superior Essex is committed to understanding how those products interact with human health and the environment, and ensuring that those interactions are positive. The company remains dedicated to these efforts by recognizing the value sustainability brings to the customers, industries and communities it serves because it operates with an understanding that the products that interconnect the world must also respect it.

Its products are based in nature, not only in terms of materials and deployment, but also in principle. Like the roots of a tree, these products form networks that often remain unseen while allowing the whole organism to flourish. From college campuses and healthcare facilities to individual homes and personal devices, communities and industries across the globe rely on Superior Essex communications cabling to stay connected, to collaborate beyond geographical boundaries, and ultimately to thrive.

20. INSPIRATION + EDUCATION IMPERATIVE

LPC Page URL: http://ce.superioressex.com/About/Environmental/

BEAUTY PETAL LESSONS LEARNED

Superior Essex will be creating an entire microsite that includes significant LPC messaging within its sustainability platform. When it is published, Superior Essex will update the LPC information on its website to include its LPC label and a brochure.

SUMMARY OF PROCESS AND BENEFIT OF PURSUING LIVING PRODUCT CHALLENGE

By achieving the Living Product Challenge certification and promoting it, for the first time A&D firms are calling Superior Essex, inviting the company to share its message, rather than the other way around. The Living Product Challenge certification displays an overall sustainability message in a clear, concise and beautiful manner within the label and Superior Essex is excited to share its achievement with the world!